Sales forecasting

and inventory optimization

Become a retail mastermind you always wanted to be.

Become a retail mastermind you always wanted to be.

By: Jul Domingo

As a retailer, you face the challenge of deciding how much quantity to buy and when to order throughout the year.

That requires referring to performance data and creating projections from it.

Monitoring your goods well is the first step. Without it, you can’t make your forecasts as accurate as possible.

And as you already know, inaccurate forecasts can cost your business a fortune.

But making them more reliable requires significant unlearning and relearning of old inventory forecasting habits, such as formula-based forecasting.

It sounds intimidating, but it isn’t really that difficult. Using smart software algorithms will solve your inventory forecasting needs to keep yourself from running out of stocks, failing to meet customer demands, and losing profit.

You can use this inventory forecasting guide to figure out what works best for your business. You’ll learn the following:

The first step in inventory forecasting is to understand the financial activities of different retail businesses. That’s because it helps you better understand how different industries sell and replace their stock during particular periods.

Over the years, we have collected data on the inventory turnover in different industries (shown in the table below). This data reveals how fast they sell inventory, on average, measured in days. Notice how the money spent on inventory represents the biggest opportunity for optimization.

| Type of Goods | Median inventory turnover (days) | Off peak inventory value as a % of annual revenue | Peak season inventory value as a % of annual revenue |

|---|---|---|---|

| Food | 15 | 3 | 7 |

| Fashion | 70 | 25 | 55 |

| Technology | 40 | 13 | 20 |

| Sport | 66 | 16 | 24 |

| DIY | 74 | 15 | 25 |

| Niche slow-moving goods | 95 | 20 | 24 |

Inventory is a never-ending cash flow story.

You sell your stocks.

Once you’ve made money from it, placing another purchase order becomes your priority.

This means a significant chunk of cash is constantly in the flow.

Inventory forecasting aims to reduce that chunk of cash without compromising the on-shelf availability of your goods. This video can help you better understand this strategy:

The next table shows how you can enhance up to 40% of your cash flow by optimizing your replenishment, which is tied to inventory forecasting. You’ll discover how this approach surpasses any other optimization opportunity for a retail business.

| Retail business expense | Opportunity for optimization |

|---|---|

| Rent | 0-10% |

| Sallaries | 0-5% |

| Transport | 0-3% |

| VAT | 0% |

| Advertising | 0-10% |

| Inventory replenishment | 30-40% |

Discover how Inventoro can help boost your cash flow by optimizing your inventory: Reduce Inventory.

Mastering your stock levels is an essential business skill for any retail business. If you know how much quantity will meet future demand, you’ll save so much time and money in the process.

That’s because inventory forecasting allows you to:

Various methods exist to create forecasts, but you can only guarantee error-free reports through smart inventory forecasting.

Make technology your best friend. Learn how to boost retail sales with smart inventory forecasting.

Sales forecasting is the first step in forecasting inventory. The only way to know how many stocks to keep is to know how much your customers need.

Sales forecasting requires an understanding of:

Identify the current consumer demand based on the factors above, so you can predict the ideal inventory levels.

Sales forecasting shouldn’t be confused with inventory forecasting. The two are related, but not the same. Inventory forecasting includes:

Consider other factors, such as seasonal sales. Holiday sales represent 19% of annual retail sales because demand increases during this time. As an example, forecasts can prevent both stockout and overstock situations during Black Friday madness.

Let’s dig deeper into the relationship between sales forecasting and inventory forecasting in the next section.

Inventory forecasting directly depends on sales forecasting.

It’s as simple as this: your sales forecasts tell you how much inventory to keep on hand. The more accurate your sales forecasting is, the more optimal your inventory can be.

Another way to put it is that the quality of your sales forecast affects the quality of your inventory forecast, which, in turn, affects the direction you take when it comes to your bottom line.

Let’s continue this inventory forecasting guide by defining three inventory terms that have left many business owners scratching their heads. These are stockouts, slow-moving products, and dead stock.

Stockouts occur when there is not enough inventory on hand. It’s the consequence of poor anticipation of consumer demand, which results in lost sales.

Slow-moving products are items sold within longer inventory days’ turnover, depending on various industries’ ideal turnover times. If they sold the products beyond that specific range, it’s already considered slow-moving.

Dead stock refers to stale products in a stockroom or warehouse that can no longer be sold. Dead stock situations occur when a company orders too much inventory and fails to sell it over time.

If your main problem is weeding out dead stock, you might want to read more of our tips here: 7 effective ways retail businesses can avoid dead stock

These inventory issues hurt your bottom line, and can easily be avoided with the help of an accurate inventory forecast. The next section includes a step-by-step guide to inventory forecasting.

Follow this 6-step checklist to scale your business by maintaining the ideal level of inventory:

But since you have a variety of products, each with different performances and market appeal, generic formulas can’t give you the accuracy you need. Your best bet would be to rely on a platform enriched with sophisticated algorithms, such as Inventoro. We select the best mathematical formula based on the individual performance of your products. After that, all that’s left for you to do is accept our recommendation.

Read further to have a complete guide on how to use inventory forecasting to scale your business in various ways. Our first stop: product segmentation.

Having the basics of inventory forecasting down pat, let’s explore this first key element for creating your replenishment list: Product segmentation.

There’s a good chance you don’t sell just one item. If you do, then you know your product inside out, forwards and backwards.

But most businesses, especially the growing ones, always want to expand their portfolio. Here’s where tracking the performance of your products can become a little messy. With product segmentation, you can see for yourself which items that deserve the highest priority and the ones you can disregard.

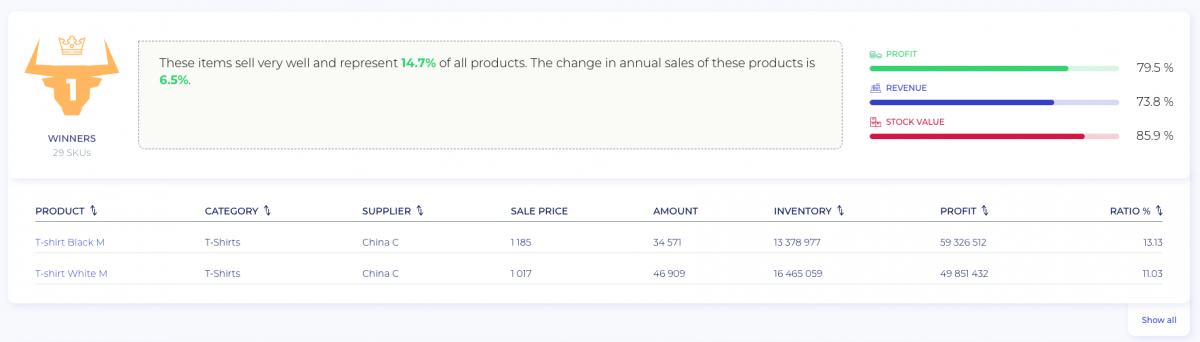

It involves putting all your products on a single long list. Your best-sellers at the top, and those that almost never sell at all at the bottom. At Inventoro, we categorize them into three different product segments:

Winners: Products that represent 80% of your sales, but don’t go over 20% of your inventory. These are your best sellers.

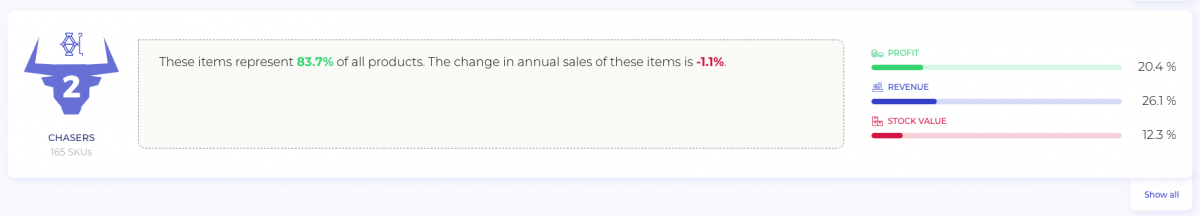

Chasers: Items with a great deal of sales potential but are not high in frequency or volume. Generally, these items contribute to the growth of your business.

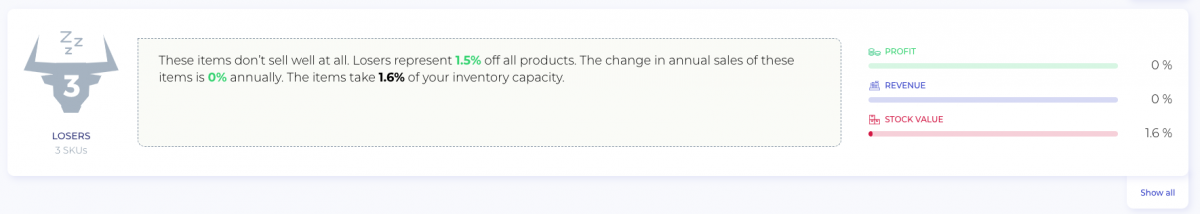

Losers: Products that sell very little or none at all. They are also known as dead stock or toxic inventory.

The segmented products show you what you need to focus on in-demand forecasting. Winners are your cash cows, so you want to have them available at all times. This means you must set a high service level for this group. Service level reflects the availability of your goods. For Winners, the ideal service level is +99%.

Chasers are somewhat important, but 100% availability of these products would no longer benefit your bottom line. So, the best service level for these is 95%. Because these products are not your best sellers, you can always expect that it’s not risky to compromise on satisfying this demand.

And then there are the Losers. You can ignore them when forecasting your inventory. These products sit on your shelves and lock up your cash. The longer your money is tied up in them, the longer you can’t use that money for more profitable purposes.

Optimizing your purchase orders through forecasts is the goal of this complete guide. Product segmentation sifts your inventory to make the forecasts more accurate and more profitable.

Product segmentation adds the concept of service level to the equation. It’s inevitable to run out of stock but with this feature, it’s cheaper and worth the risk. You just have to identify the products that can and can’t tolerate stockouts under all circumstances.

Learn more about how Inventoro can help you categorize your products: Product Segmentation.

Forecasting inventory does not only take place per item, but also per stock-keeping unit (SKU). This refers to items in a warehouse, not per business.

If you move an item to a different location, you create two different SKUs: one at the former warehouse, and another at the new one.

Here’s an example:

Imagine you sell t-shirts in five sizes of one model, and your business caters to online and offline customers. Because of this, you keep your items in two different locations: an ecommerce shop and a high street boutique.

A single t-shirt design of five sizes in two locations represents 10 SKUs. Each location (point of sales) has a different sales forecast, so there should be separate inventory forecasting for each of them.

Using the same example, imagine this scenario:

Your sales forecast tells you that your business will sell 100 t-shirts next month. But you sell your goods both in your online store and in your brick-and-mortar shop downtown. So you might think: “OK, I’m going to keep half of those shirts in my e-shop warehouse and leave the other half in the shop downtown.”

But hold your horses, sales don’t happen as instinctively as that. If you run the sales forecast for each of your locations independently, you will find that 83 t-shirts were predicted to sell online, but only 17 in your downtown store.

Sticking with your original assumption will lead to 33 overstocks in the brick-and-mortar shop and 33 stockouts online.

Locations are critical for inventory forecasting, so forecast your sales to the smallest inventory component possible to get them right. If you have thousands of SKUs, it’s almost impossible to get them right off the top of your head.

Forecasting using Excel might work as well software on a single item because you know all too well how t-shirts sell. But that’s wishful thinking to try with all your items–SKU by SKU, Location by location. It’s simply beyond the capabilities of one human mind, even if you’re the t-shirt expert.

Artificial intelligence is your solution for that. Make data-driven solutions. Rely on real data. With a software solution like Inventoro, you’re ready to do inventory forecasting the smart way. The only way the biggest retail organizations have been doing it for years.

When considering your inventory, you usually pay more attention to numbers and cash because they affect your bottom line.

Did you know there is another factor of equal importance? Your customers.

The basic logic here is that the more satisfied your customers are, the higher their likelihood of returning to do business with you again.

But how can you attract and satisfy them? Perhaps you can boost your pay-per-click campaigns to the maximum. Or, you can go to extreme lengths and discount your products making every Friday a Black Friday.

Sure, both tactics are likely to have a positive sales effect. But let’s admit it—they’re going to cost your business a lot. The more you rely on them, the less profit you’ll make.

What you want is for your customers to come back without hurting your resources.

If you can observe most e-commerce businesses, those that generate the most direct traffic are the ones that dominate the market.

Your first step is to be the first choice for your customers by having what they need when they need them. This way, create a loyal following that will allow you to charge more and spend less on your marketing. According to this study, not having available stocks has negative effects on retailers. So focus on not running out of your customers’ favorite products.

Here’s a list of factors that affect customer satisfaction in a typical online business. Pay careful attention to the ones associated with inventory forecasting:

| Price | not associated |

| Number of items on sale | associated |

| Availability of products | associated |

| Customer support | not associated |

| Accessibility and UX | not associated |

Customers prefer to buy their goods all in one place. They don’t enjoy visiting several shops to find the item they want—whether it’s online or in a brick-and-mortar. It takes too much time (ecommerce) or it increases transportation costs (in-person shopping).

An online shop selling 10 items can never compete with one that offers 10,000 product listings. Scale is an enormous factor for success. But the more products you offer, the more complicated it gets to keep everything in stock—product segments and SKUs, remember?

That’s where inventory forecasting plays a vital role. It’s a useful tool to keep your customers satisfied with the number of items you have on sale. Save yourself the trouble of managing and predicting heaps of different inventory levels with forecasting.

Customers expect to receive their goods immediately after purchasing them. It’s for this reason some e-commerce companies now offer same-day shipping. This sets them apart while everyone else hustles over the two-week delivery competition.

As customers, we’ve all been there—if we can’t have the most convenient shopping experience, we simply switch to competitors. With accurate demand forecasting, you can have the confidence that all your best-selling items are always available on hand for your customers.

Inventory forecasting has a powerful feedback mechanism that builds customer loyalty over time by satisfying their demand. This direct effect on customer satisfaction can lead to more frequent sales and less pricey customer retention.

Want to know more how your inventory affects customer satisfaction? Learn more about how Inventoro can boost customer satisfaction here.

Inventory forecasting is an excellent tool for promotion planning.

From what we know through years of experience working with our clients, everybody is eager to offer discounts. But rarely do businesses actually apply any mathematics to the process before they do so.

When planning promotions, businesses need to concentrate on these questions:

All these questions are directly associated with inventory forecasts. The last two questions, especially, are the ones that influence the profitability of your price promotion. You can only understand the total effect of your discount strategies with the help of demand forecasting.

Replenishment is the process of placing orders with your suppliers. Manually performing this process is time-consuming and inefficient, so most businesses make use of smart algorithms to handle this essential but tedious task.

Despite having a smart system to help support your decisions, the level of automation will remain completely up to you. Certain manual approval processes still have to take place if you wish to opt-out of this futuristic technology. But even if you know more than the algorithms do, is it really your best choice to process your reorders manually from time to time?

After sales forecasting, analyze the product segmentation. Next step is factoring in the minimum order quantities and lead times.

After completing these three steps, most inventory forecasting software stops will hand you your replenishment list, so you can begin placing those orders manually.

But doing it manually takes time and effort, and leaves a lot of room for errors. Each supplier requires a different order format. Some demand an email, some require you to enter their B2B portal and place your orders there. These orders are repetitive tasks and automation makes things way easier for you.

Inventoro offers automation, so all you have to do is approve the list and let the machines place the orders.

If you want to know how this works, you can read more here: Inventoro – Automated Replenishment.

It’s unlikely that you switch suppliers every month. Automated replenishments allow you to tailor everything to your existing suppliers’ needs, and the system creates purchase order list for you, usually in a table format that matches the prerequisites of your suppliers.

When you approve the list, you can automatically send the table to an “if-this-then-that” online system for further formatting. Our clients typically use Zapier or Integromat for this purpose.

Zapier takes your table, reads the lines, and turns them into specific order formats based on your suppliers’ criteria. It creates an email, a digitally signed purchase order—or any specific output you want. Once done, the system automatically sends the purchase order to your supplier.

The best part: All of this happens in one click.

Zapier and Integromat usually offer a free plan for smaller businesses. Our clients often fit into this category. At the end of the day, automated replenishment together with inventory forecasting can save you a substantial amount of time compared to manual replenishment.

The goal of this inventory forecasting guide on replenishment is to help you decide if automated inventory forecasting is right for you. If you wish to start, our software will assist you in the entire process right away. All you need to do is connect your inventory data via an API or .csv.

Be sure to watch this video first if you want a better understanding of the key functions of our inventory forecasting system.

Before you go, here are extra tips to help optimize your inventory in 2022:

The best inventory analysis method requires trial and error. You can consider the ABC method, which is the most popular one. By ranking the products that give you the highest to lowest revenue, you’ll get A, B, and C as your winners, chasers, and losers, respectively.

Another method is the Economic Order Quantity (EOQ). This method considers other expenses, such as ordering and holding costs. The variables define the right time and the right amount of purchase orders with the lowest cost possible. Learn more about EOQ formulas here.

As with the previous year, 2022 will be riddles with challenges from the pandemic. Monitor your sales velocity, which refers to how long it takes your team to turn sales opportunities into closed deals. It gives in-depth insights into the sales cycle to come up with more accurate demand forecasting.

Sales velocity = (Opportunities x Average deals x Conversion rate)

/ Sales cycle

You must also consider market competition and seasonality. Is there a latest product trend? Is there a surge of customers due to seasonal demand? Always update your historical data and align them with these variables.

And don’t forget external factors, such as worsening supply chain problems seen in 2021.

Your inventory forecasting should have a clear period for each specific product. Identify the basis year of the historical data in your forecast. Are you going to predict your inventory for the first quarter of 2022 using the data from the last quarter of 2021? Or the last six months?

A forecast’s quality changes over time depending on how well the new actual sales match the forecast. Think about the variables that affected the recent change in the actual demand from your previous prediction. Ex: Demand drastically changed during the rise of Covid-19, so you can’t use the same parameters you had in the pre-Covid era.

Inventory management software is an advanced way to create your forecasts. It considers a ton of variables before it produces the most optimal inventory level without the risk of errors. Consider these numbers, for instance:

| Inventory size managed by human insight and experience | no optimization |

| Inventory size managed by Excel spreadsheet | 8% optimization potential |

| Inventory size managed using an algorithmic forecast | 30% optimization potential |

Inventoro takes the stress out of inventory forecasting–with a 30% optimization potential. Let the experts handle the crucial technical and mathematical parts.

With all the uncertainty around us, inventory management software can help give a sense of security. Here’s how Inventoro’s smart algorithms can strengthen your inventory management:

Optimized inventory management: auto stock replenishment, timely and automatic reorders, efficient forecast per item and per SKUs

Smart product segmentation: Strategic control over the most profitable items, simplified supply chain management

Accurate demand forecasts: Free from human error, reduced stockouts and dead stocks, product portfolio growth

Integration and task automation: Customized purchase orders, smart integrations for updating and reporting

Real-time inventory valuation: effective inventory reduction, prevents fluctuations in inventory levels, high customer fulfillment rate

Forecast the optimum level of your inventory with a demo or visit our blog for the latest tips.

Become a retail mastermind you always wanted to be.