Sales forecasting

and inventory optimization

Become a retail mastermind you always wanted to be.

Become a retail mastermind you always wanted to be.

Written by: Jul Domingo

Your inventory should meet Goldilocks’ standards – not too hot or too cold, just right.

Having adequate inventory on hand is essential so that you can meet demand and backorders won’t occur, both of which contribute to profitability.

“Inventory forecasting is the largest opportunity to increase sales in a short time span.”

– Radim Jung, Inventoro Co-Founder

Nevertheless, it’s not easy to predict the right number of stocks, especially since the process requires a great deal of energy and time.

According to a 2019 Bossa Nova survey, 67% of companies believe their employees shouldn’t invest too much time analyzing inventory.

If this is true for large companies, it’s even more relevant for smaller businesses with limited resources and staffing.

Smart inventory forecasting is key here. With the right tool, planning demand becomes a breeze while also allowing you to leverage accurate forecasting.

Marquis Matson, Sozy’s VP of Growth shares: “We typically use forecasting software and just run things more conservative than need be. Having enough inventory to fully capitalize on advertising-efficient months is the best, having too little strains your ability to grow.”

How do you make smart inventory forecasting a part of your business strategy and use it to generate more revenue? Here’s what we’ll cover in this guide:

Retailers rely on forecasting to prepare for the future, and that comes as no surprise. The two most relevant forecasting techniques are sales forecasting and inventory forecasting (also called demand forecasting). Based on these forecasts, you can calculate how much profit your company stands to make.

While the two are closely related, the resulting numbers may differ in many situations. Finding the distinction is essential for achieving a level of accuracy that improves business performance.

Sales forecasting involves making an informed prediction of the sales you’ll generate over a given period. It’s often easier to undertake than inventory forecasting. Observing your historical sales data can give you a good idea of what to expect in the future.

Therefore, getting a complete picture of the situation begins with this step. But in order to have a 360-degree view of your performance, or rather what could have been your performance… you need inventory forecasting.

It helps you factor in relevant data such as sales trends, future events, and most importantly, loss of sales due to stockouts. By doing so, you don’t have to go through the same mistakes and are likely to boost sales exponentially.

Vino Jeyapalan of Kabo Fresh Dog Food, an online meal delivery subscription for dogs, sums it up really well: “Understanding your inventory will help you understand how you can leverage capital better to grow your business.”

Sales and demand forecasting are often interchangeable, but sometimes they aren’t.

And here’s the kicker: It’s exactly the situation when demand forecasting is different from sales forecasting that deserves special attention.

This is especially true when it comes to brick-and-mortar shops. Unlike e-commerce stores, it’s not easy for retailers to detect when customers wander in and leave because the product they want to purchase is currently unavailable. And this affects customer satisfaction. In fact, 21% to 43% of customers will shop elsewhere when faced with a stockout.

At the end of the day, however, both forecasts are essential in order to increase sales while minimizing inventory – which is what every business owner wants to achieve.

“From my experience, both are equally important to understand the direction your business is heading and how you can support it. Understanding your past inventory behavior from turnover to seasonalities is best utilized when you compound it with sales forecasting to see what you need to build for the next scale,” Jeyapalan shares.

To manage your business effectively, you must have accurate sales forecasts to plan ahead and track your finances and inventory.

Then you need to combine your sales forecasts and missed sales projections to develop reliable inventory forecasts.

To predict demand, there are a handful of factors at play. All of which are important to set forecast boundaries and improve accuracy. These are:

Forecast period refers to the period of time over which inventory needs to be estimated. It can be done monthly, quarterly, and annually.

When choosing the right forecast period, consider the following:

– Production cycle (if applicable)

– Inventory turnover rate

– Merchandise performance

– Suppliers’ lead times

Ideally, the maximum stock level is the inventory count in a bin or on a shelf once it’s full of a specific item. Small businesses tend to have less inventory space and funds than retail chains, so their maximum stock level tends to be lower.

Trends describe how the market changes over time. One example is seasonal trends. “There is usually slower consumer demand for vehicles around year-end because of Christmas shopping competition, but on the opposite side, there is stronger demand around March because of higher availability of funds due to tax refunds being issued,” according to Mark Beneke, owner of Westland Auto Sales.

Since the sales from these months can be attributed to a certain cause, they can forecast future sales and adjust their inventory based on their past sales.

When fulfilling orders, your inventory depletes, so you may need to replenish it if it falls below a certain level. The reorder point suggests when to place an order to avoid running out of stock.

Some of the things you need to consider are:

– Lead times your manufacturer, vendor, or supplier needs to send you products

– Time it takes for your warehouse, distribution center, or retailer fulfillment company to receive inventory, if applicable

– Amount of safety stock you keep in your inventory to avoid stockouts

– Amount of sales that particular item makes on an average day

Multiple factors could affect the data in the future, which is why it’s important to include them when forecasting inventory levels. For instance, sales velocity gives business owners a sense of how much a product sells after being in stock for a while.

“Using sales velocity, we can predict how much of the product should be kept in inventory so we can avoid a stockout before it happens,” Parenting Nerd Co-Founder, Elizabeth Hicks shares.

In addition, you should also consider your marketing activities, publicity, events, and other factors that can influence a product’s demand. For instance, each product responds to discounts differently – which makes it harder to predict how much you need to have in stock once you run a promotion.

Clearly, predicting future demands requires careful estimation and analysis. While success in this area is very important for your business – it can be a heavy burden to carry on your shoulders. This is often the case for small and medium-sized business owners.

It takes a lot of work but being the only one who can ensure your inventory forecasting doesn’t go off the rails, you soldier on. And you end up spending too much time and energy establishing this part of your business… month after month, quarter after quarter, year after year.

We’re talking about the time and energy that you can spend growing your business.

Additionally, making mistakes is likely to happen, especially when you’re wearing multiple hats to manage your business. Keeping track of the forecast period, reorder points, trends, and so on can be a lot for one person.

Here’s the good news: The changing times and the advent of innovation have seen artificial intelligence taking over the inventory forecasting process, which traditionally relies on manual methods.

“Today, artificial intelligence is simplifying the forecasting process. Popular demand forecasting methods include deep learning and differentiable programming. With the help of artificial intelligence, companies are now collecting and using business intelligence from various sources. This ability allows them to make predictions based on historical data, past market trends, and even the weather,” shares Physician Thrive CEO and Financial Expert Justin Nabity.

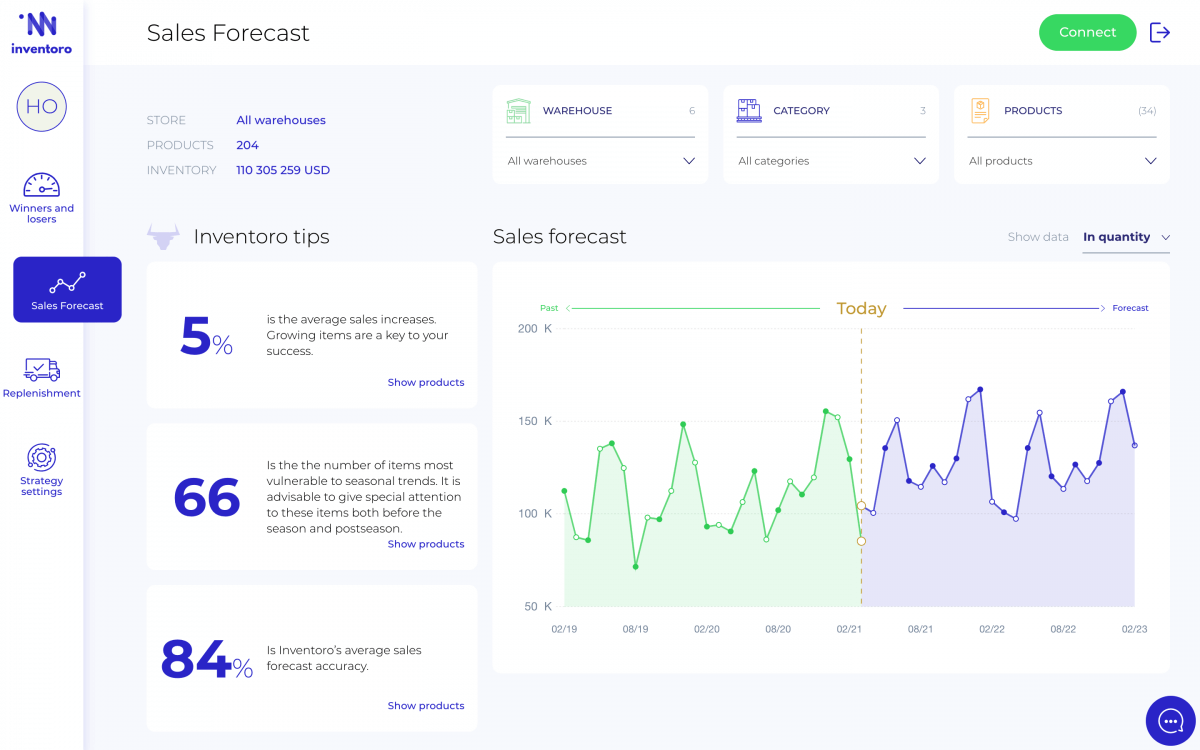

So do yourself a favor and arm yourself with a reliable forecasting and optimization tool. Look into Inventoro, which automates the process of factoring all the relevant data, so you don’t have to keep track of them yourself. It uses machine-learning algorithms to improve forecast accuracy, allowing you to buy less and make more money in the long run.

This means you can avoid stockouts and get rid of dead inventory while also freeing up to 20 hours of administration – giving you back precious time that you can now use to scale your business.

Step 1: Analyze your company’s sales and performance

Step 2: Know your market and customers

Step 3: Assess your product portfolio

Step 4: Plan your strategies according to your inventory forecast

The first step of forecasting is to set a baseline simply because a lack of data makes it difficult to make informed forecasts and predictions.

“Our company makes use of sales metrics to analyze company sales and demand forecasting. Sales target, product performance, and sales growth are some of the metrics which have helped us make well-informed decisions about future demand.” explains Andrew Priobrazhenskyi, CEO of online marketplace DiscountReactor. “If the product performance is positive and increasing, it’s evident that we have to stock up its inventory.”

Traditionally, you have to manually include external factors such as the weather, holidays, and economic downturns – which means you can underestimate or overestimate your inventory if you don’t check everything off.

And as you already know: This is bad for business.

“Having too little inventory can slow your growth, but having too much inventory can kill you, so we stay in the conservative side.”

– Marquis Matson, VP of Growth and Content Lead at Live Sozy

Jeyapalan also shares a story: “In our first year, we had our first-hand experience of inventory planning gone wrong. Without an iterative review process, we faced our biggest inventory challenge where our demand planning was over forecasting quantities. If we continued down that path, we would have been cashless in a matter of months.”

Most businesses struggle to stay afloat during the initial COVID-19 outbreak because of excess inventory.

In the United States alone, it was estimated that $8trn worth of goods were parked for sale during the shutdown. And even as the economy recovers, most businesses, especially the small ones, continue to experience a lack of accurate inventory forecasting.

With automation tools, this can be avoided. “Our system has no problem with the pandemic. Our algorithms forecast long-term as well as micro-term sales differences. So we adapt very, very fast. Something which makes us strong and differs us from the competition.” Inventoro co-founder Radim Jung explains. “We don’t forecast only on what has been sold, but also what could have been sold if it were available. This translates into “automatic stockout detection.”

As a rule, you need to look at your inventory metrics, which will give you a sneak peek of product performance, lost sales, stock turn, and sell-through rate. Unfortunately, performing this task manually is labor-intensive and potentially error-prone.

With smart inventory forecasting, you won’t have to. For instance, Inventoro provides you with sophisticated software that forecasts what you can sell within the next few weeks and months based on your data. In addition, the scoring system is continually evaluated to ensure it’s giving you more accurate results day after day.

Market research is a method used in determining the audience’s response to a particular product or service.

Nabity stressed the importance of performing market research: “The information obtained from market research can then be used for tailoring marketing strategies to your organization’s liking.”

It lets you figure out which new products and trends your market is interested in while also reducing risks and increasing profitability as you assemble your inventory.

“Furthermore, continuous analysis of inventory turnover, regular stock counts, and other trends in your customers’ orders can help you make short- and long-term planning more accurately,” Nabity adds.

On the other hand, a study involving retail pharmacies during COVID-19 proves customer behavior affects inventory. It examined how COVID-19 and consumer behavior (such as hoarding face masks, sanitizers, and protective gears) has had significant impacts on drug inventory management in Bangladeshi drug stores.

While the pandemic is undoubtedly a rare occurrence. It’s still critical to understand what your customers like and what they tend to buy to forecast demand effectively. Ask yourself the following questions:

– What are target shoppers’ preferences (in my area, for physical retailers)?

– Does my customer base change seasonally or not?

– Are my prospective customers quick to catch up with trends?

This information may likely be available through your POS systems and past sales analysis. Aside from this, you can also examine your business internally to see how it is doing and what your objectives are. Alec Pow, CEO of The Pricer, suggests you consider the following questions:

– This year, how many new clients do you expect to bring in?

– How many did you get the year before?

– Have you hired new salespeople, boosted your brand’s visibility, or increased your chances of attracting new customers?

In any business, it’s normal to adjust your inventory to match your revised sales forecast. But before you do that, you should take a hard look at what’s selling like hotcakes and what’s not doing so great.

As a small business manager or owner, you must fully understand your product portfolio’s strengths and weaknesses. The goal here is two-fold: Find out your money-makers and weed out the aging inventory in your store and warehouse.

Looking at your accounting journals for purchasing and sales is a good start, but you don’t have to go through all that trouble if you choose to do smart inventory forecasting.

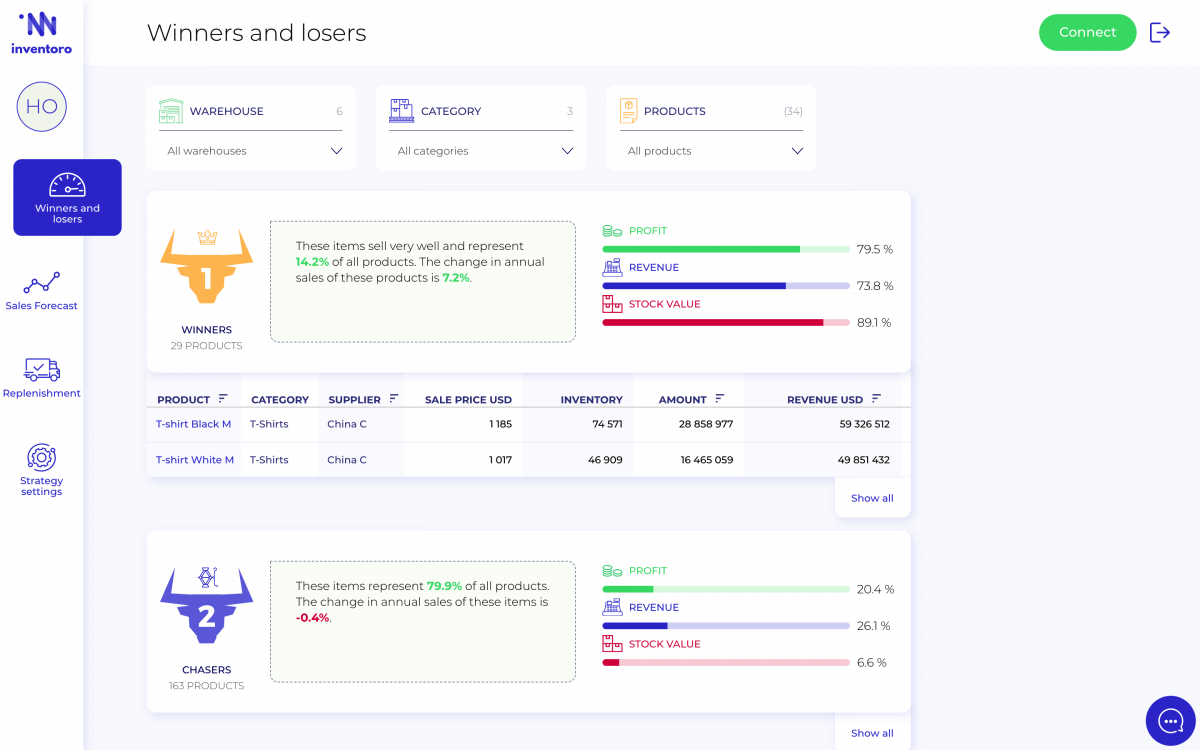

For instance, Inventoro’s product segmentation feature called Winners and Losers is handy for this step. You can filter your portfolio by profitability, sales frequency, or revenue share with just one click. That means you can see your top-performing and ineffective products in seconds instead of spending grueling hours poring over your accounting journals.

Now that you’ve gathered all the relevant insights, it’s time to tie everything together and package it in a more profitable strategy.

By looking at the sales forecast and understanding customer behavior, you can predict future sales and determine which products your target shoppers will buy next. This will allow you to replenish your stocks accordingly.

Knowing which products are selling well and which are not allows you to make adjustments to your inventory, as well. This means you can focus on your productive inventory and eliminate the underperforming ones.

“Before marketing our products, we utilize all the data to determine inventory levels so that even when we are over-advertising a product, we know that there is sufficient stock to cater to customers’ needs.”

– Andrew Priobrazhenskyi, CEO of DiscountReactor

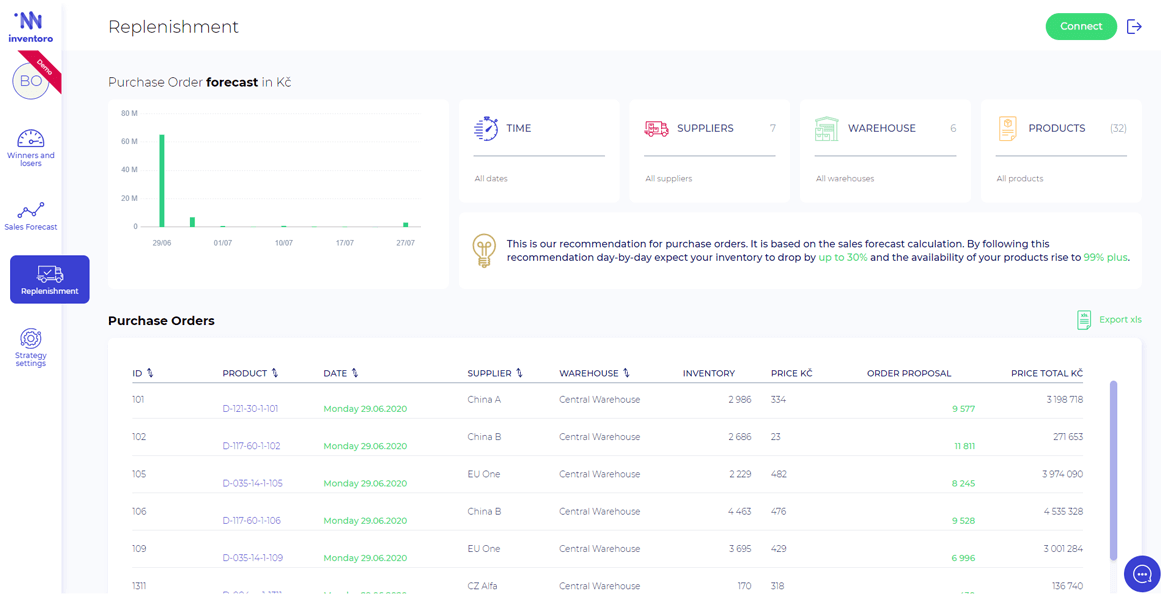

Inventoro features a replenishment system, which brings all these relevant insights together. When you integrate the sales forecast function with product segmentation and other key metrics, you end up with the perfect purchase order list each day.

And if you follow the recommendations religiously, it can increase your profits in two ways:

– Save money by cutting out products that are not performing well.

– Make money by boosting your stock of profitable products.

What’s even better is that you can automate the replenishment process so that you can focus on your other responsibilities as a business owner. SMB owners should consider this because 72% of stockouts result from inefficient ordering and replenishment, with some retailers ordering too little or too late.

You can also use the forecasts to adjust your marketing strategy. “When I receive the inventory forecast numbers for the season, I compare them with the sales projection from my marketing strategy. If the sales projection is higher than the inventory forecast, I scale some of the marketing efforts back to match with it. These two metrics must match to avoid any sales disaster,” Hicks suggests.

Beneke seconds this idea: “More specifically, it allows us the ability to predict the type of inventory that has the potential to produce the best results based on the previous year and current standing. This type of inventory will also affect how our ads might be made.”

After discovering which products don’t do well or have a short shelf-life, you can develop creative ways to move them. For example, you can offer discounts and bundled deals, so you get rid of them and make a profit simultaneously.

But once you shift to smart inventory forecasting, you don’t have to worry about having dead or outdated inventory.

Financial analysts can help analyze data and perform tasks such as financial forecasting and operational metrics tracking to make good investment and business decisions. They also add a human touch to smart inventory forecasting – making it more effective.

Your frontline team has a front-row seat to the show. They have a pretty good idea of which product categories are faring well based on customer behavior. Therefore, involve your employees in both sales forecasting and demand planning. Perform surveys or meet up with them to discuss product performances.

We’re likely to generate data discrepancies when we do things manually. It’s just human nature. Aside from potential errors, it’s also stressful for SMB owners to have that responsibility hanging over their heads in addition to their other responsibilities.

By leveraging technology, you can centralize your data and streamline your operations. “Choosing the right software helps you replenish the inventory at the right time and in the right quantity, which can be a game-changer for your business,” Priobrazhenskyi agrees.

“Machine learning uses traditional statistical data and company-specific past data to predict inventory forecasts, which is much more efficient than doing it manually.”

– Elizabeth Hicks, Parenting Nerd Co-Founder

Tools like Inventoro can simplify the process. Inventoro can optimize your inventory by helping with sales forecasting, product segmentation, and replenishment. Our goal is to help you increase your profits by teaching how to buy minimum and sell maximum. We even released a new handy feature appropriately called Gold Brick to show you how much money you can save if you follow our replenishment advice.

You can learn more about how Inventoro can transform your business into a data-driven one, download our ebook: Supply Chain: Chasing Giants.

Become a retail mastermind you always wanted to be.