Sales forecasting

and inventory optimization

Become a retail mastermind you always wanted to be.

Become a retail mastermind you always wanted to be.

Written By: Jul Domingo

Retailers’ hoarding habits have now spread to warehouses. After stocking up on goods ahead of supply chain disruptions, they’re scrambling to find a home for their mountains of merchandise.

Big-box retailers had been dubbed big property retailers for this very reason. As a growing business, it’s tempting to join the bandwagon. The benefits may outweigh the costs of getting a new warehouse.

But, hold on a second: Does business expansion inherently require leasing, renting, or even, purchasing a new warehouse?

There’s simply no universal answer. It depends on various factors that we’ll discuss in this blog post. And if you realize that you need one anyway, we have listed some factors to consider before taking the plunge.

Not sure if you need a warehouse? Read 5 considerations before investing in a new warehouse

Convinced you need one? Go to 4 tips when looking for a new warehouse.

Let’s look at customer demand and how it relates to delivery speed. Generally speaking, shoppers are willing to pay 2.2% to 5% more for fast delivery products. But the situation may not be as clear-cut as it seems.

To find out which category your products fall under, answer the following questions:

Chances are that if you sell a unique product, there’s no real urgency for your customers. They will wait, knowing what they’re getting is something they won’t find elsewhere.

Imagine you run a business that specializes in selling collectible sneakers. Shoppers are unlikely to choose faster shipping over your credibility. If they opt for another company, they might end up with a pair of dupes.

Other examples include specialized DTC brands (ex: Wonderbelly, a supplement manufacturer that destigmatizes gut health issues) and personalized goods (ex: Benchmade for bespoke knives). If this is the case, then getting delivery to your customers faster isn’t important right now.

On the other hand, you face fierce competition if your business sells a commodity, such as food items and fashion merchandise. Acting fast is paramount for success because it influences your target audience’s buying decision–especially since Amazon Prime’s 1 to 2 business day delivery policy sets the bar high for customers.

In this case, it makes sense to add a new warehouse if that means being able to deliver at a much faster rate, and satisfying 48% of consumers who consider 2 to 3 days as the standard shipping period.

However, this can pose a challenge for retailers who sell both types of goods. In such a situation, a deep dive into your product portfolio is recommended. We’ll talk more about this later on.

The number of SKUs influences warehouse operation complexities. This especially gets muddy when you’re dealing with different types of products and styles.

How do you plan to distribute your products among your warehouses? For instance, if you sell sporting goods in the US, you should find out what people’s favorite hobbies are in each state.

Your warehouse in Colorado can carry running accessories and hiking goods (neighboring Arizona is home to plenty of outdoor enthusiasts). Your Nebraska warehouse will likely hold ski equipment. And your Florida warehouse, some diving gear. That’s not to say, you shouldn’t offer a healthy mix of products in every warehouse–but how much of them should you need per warehouse?

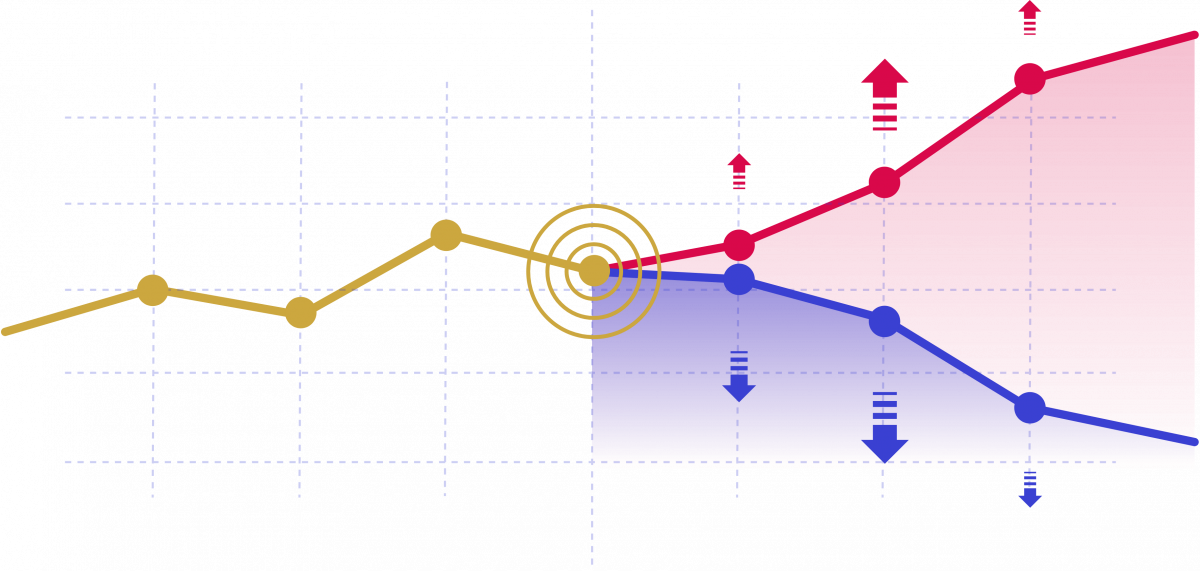

Enter: sales forecasting. Sound forecasting and simulation strategies can help you distribute inventory effectively among several facilities. You need a platform, such as Inventoro, that can enable you to forecast overall sales, but at the same time, zoom in on each warehouse.

Besides discovering how to balance inventory effectively, it’ll also help you maintain a healthy inventory buffer for your warehouses. Let’s picture a different scenario: You have enough inventory in your main warehouse for a slow-moving item. But you have four other warehouses. You decided to increase the amount for each website by a few “just to be on the safe side.” This move raises carrying costs and takes away the opportunity to house more profitable products in your storage facilities.

As you can see, a lack of strategic foresight can result in many significant problems for a company. So before investing in a new warehouse, make sure you can forecast which products you’ll need to stock it with first.

Leasing/renting, let alone buying, a new facility is expensive. So before you jump on the latest retail fad that is warehouse hoarding, make sure your current warehouses are *truly* filled to capacity. Or that there’s nothing else you can do to optimize your space.

For instance, if you set up warehouses per product, you’re ignoring valuable real estate. You can fill an entire warehouse with an outstanding product–no sweat. But when they fly off the shelves, you’re essentially sitting on money (and potential) as you work on restocking them.

Even if we flip the coin–if you keep your outdated products in one place, you’re still sitting on the same valuable assets. Your existing warehouse/s should be set up with a more optimal set of operations, such as dynamic storage, before you begin looking for a new one.

Assuming you already use dynamic location, does that mean you have reached maximum storage capacity? Not entirely. Look at your warehouse layout. There might be some spaces you could optimize to make room for new stocks.

Some lowest-hanging fruits for finding those hidden storage ideas are changing your storage racks, increasing the height of your racks, and narrowing aisle width. Note: Make sure you’ve researched the facility, the products, and storage containers before making any adjustments.

Costs in this regard don’t mean repair costs or operating expenses. When you’re unsure whether you need a new warehouse for your products, you need to weigh the cost of adding a new facility along with the additional inbound freight and the current outbound parcel delivery costs for moving your products throughout the supply chain.

Many factors, such as speedy delivery times, point to the need for more warehouses and distribution centers. But ultimately, are you doing yourself a favor?

Imagine extra costs from potential problems, such as fulfilling six orders when the warehouse only has two. How will you pull these products across multiple warehouses and get them in the hands of your customers?

If ultimately, you realize the costs are greater, a new warehouse could create more problems for you.

Freeing your current warehouse of outdated products sounds intuitive, and it should be–but it’s not. The phrase “out of sight, out of mind” comes into play here. It’s easy to ignore the inventory hiding in your warehouse and worry about stockouts instead.

So if your warehouse concerns revolve around overflowing inventory, clear your portfolio of underperforming stocks first. Segment your products using ABC analysis to rank items based on demand, cost, and risk. What you see at the bottom are your least promising products and must be converted into profit and exited from your warehouse as soon as possible.

To make the process more reliable, you can automate it as well. A tool like Inventoro will allow you to understand your portfolio dynamics more quickly, so you can make fast and informed decisions with real-time data. This way, you can plan better which products to discount or package into bundles.

Discover more creative ideas for disposing of overstocks or dead stocks here. And find out how to prevent them from creeping back into your warehouse here.

If you answered “YES” to most of the questions above, moving to a bigger warehouse or getting an extra one is a sensible next step. Here are four important tips to consider:

First, let’s clarify the difference between renting and leasing. Both are commonly used interchangeably to describe using a piece of property that the user didn’t purchase. But there’s a nuance to the subject that gets overlooked: duration. Technically speaking, rental agreements are for short periods of time. Leasing, on the other hand, usually lasts for a year or more. It’s a fixed agreement and doesn’t allow for much flexibility.

When to rent: If you know there will be busy periods during the year (For example: the Christmas holiday), consider renting a warehouse to make room for incoming stock.

When to lease: Generally speaking, leasing is the most flexible. Upkeep is usually included in the lease (although, repairs aren’t). Should you outgrow the warehouse or decide to go in a different direction, you can scale back and move on anytime without affecting your finances.

When to buy: If land values are rising and lease prices are steep in your chosen location, consider buying a warehouse. If you don’t need the space, you can lease it in the future. Buying also gives you more control over the layout of the site.

Don’t sign on the dotted line without knowing the financial ramifications of getting a new warehouse. Here are some estimates of the costs associated with leasing a new storage space (according to logistics real estate company, Prologis):

Determine if utilities and maintenance are covered by the lease or whether they have to be paid separately. On the other hand, purchasing a warehouse costs between $625,000 and $750,000 for 5,000 square feet.

A not-so-fun fact: Not every warehouse can handle your merchandise. So this is a crucial factor to consider when you have a wide portfolio. Special facilities, as well as warehouse activities related to caring for your product while in transit, are much bigger concerns than cost. Because, understandably, these extras drive up pricing when leasing or purchasing warehouse space.

So take a look at your products and assess what their needs are. Do you have perishable items that might need cold storage? Or items that must be handled carefully, like glassware? Fire alarms and sprinklers are necessary if you carry flammable items. To ensure nothing is overlooked, refer to legally mandated warehouse regulations.

The location should take center stage when looking for a new warehouse. It affects both inbound and outbound shipments and the associated costs and time.

Consequently, the choice of a location should be strategic. For instance, small businesses might be better served by having warehouses near their stores.

Those whose businesses have an extensive online presence will have a harder time finding warehouses. Because a distributed market means finding the sweet spot that caters to different regions.

Product segmentation works to this effect. For instance, our tool, Inventoro, can help you adjust your bestsellers according to location. Instead of stepping back and looking at your portfolio as a whole, you’ll gain a better view of product performance per region. Combine it with sales forecasting, and you’ll have a clearer view of where to place a potential new hub of your operations. One that enables you to easily ship products from your factory and reach consumers quickly.

Whether you’re on the fence if you need a warehouse or not sure how to find the best spot for a new one, we’ve got your back. Inventoro can assist with forecasting and product segmentation to optimize your warehouse space or help you find a location. Get a demo today.

Fill out this brief five-point questionnaire. If you answer “yes” to more than one question, move on to the next part of this blog post. (We’ve got some handy tips to help you find the right warehouse.)

Become a retail mastermind you always wanted to be.