Sales forecasting

and inventory optimization

Become a retail mastermind you always wanted to be.

Become a retail mastermind you always wanted to be.

Written By: Jul Domingo

Overstocking, or inventory bloat, hurts your bottom line. Even big-box retailers such as Target can’t survive its wrath. By June 2022, the retail giant had resorted to swift measures to reduce excess inventory, including slashing prices and canceling previous orders from suppliers.

Truth is, business owners tend to focus on what they don’t have more than what they have. Stockout situations seem to be a priority, but overage concerns take the back seat. If there’s anything we can learn from the gaffe Target made during the post-pandemic recession, it’s that retail overstock can be just as damaging.

In case the struggles of these major retailers have given you a wake-up call, we’ve listed 8 ways to help avoid overstocks by optimizing your stock levels. These best practices will reduce the cost of overstock and boost your cash flow and gross margin in the long run.

Overstocking occurs when retailers accumulate more inventory than they can sell. The excess inventory piles up on shelves or in the warehouse for an indefinite time.

The tricky part is that it’s not immediately obvious. Quite often, these small piles of inventory go unnoticed. And they only become an issue once they’ve taken over the warehouse. Their effects, however, are outright. Overstocks, recognized or not, eat up cash in many ways. First, this outlay generates no revenue, resulting in a significant profit loss. Second, housing them in your warehouse attracts carrying costs.

The cost of overstock also depends on your industry. For instance, those that sell perishable goods, like grocery stores, incur waste disposal costs to get rid of expired or spoiled items properly. While others with multiple SKUs (e.g., clothing retailers) or bulky products (e.g., upholstery and furniture shops) have to pay exorbitant storage costs, such as rent and utilities, while waiting to sell their merchandise.

The truth is, overstocking doesn’t happen overnight. It’s a combination of factors that snowballed over time. Before formulating strategies to prevent overstocking, we’d have to delve deeper into its causes.

Overstocking causes can be internal, external, or both. Internal factors include the company’s flawed acquisition and sales processes, while external factors can originate from inevitable supply chain delays. Below are a few real-world examples that most retailers overlook over time.

Inevitable or not, consistent efforts can mitigate the consequences of overstocking. Overcome internal and supply chain challenges and maintain optimal stock levels by leveraging the strategies outlined below.

Knowing what overstock is, and its causes can help you reduce, or better yet, avoid its consequences. The goal of this section is to teach you how to optimize your inventory management and maintain the ideal stock levels at all times with the following steps: Brainstorm and list your current challenges, so it’s easier to find the best technique that suits your needs.

The dangers of overstocking begin when you don’t know how much inventory is enough to meet future orders. Sales forecasting offers an answer to this problem by providing the ideal minimum and maximum stock levels for a specific period.

Forecasting demand requires data on historical sales, seasonal trends, and marketing promotions. These factors are crucial to avoid having biased forecasts, which are just as bad as not having one. Purchasing decisions induced by hindsight bias have a domino effect, bleeding your bank account in the long run. So, the secret sauce is this: stop relying on average past sales alone.

Pay attention to each product and recognize recurring consumer trends and economic growth over time (we’ll discuss this in more detail later on). Do you have new product launches and active marketing campaigns that may fluctuate this year’s sales? Is the market economy unstable? A smart tool like Inventoro can help you analyze what’s driving sales for individual items, factoring in those fleeting trends. Improve your forecasts with real-time variables to avoid overcompensating your predictions with unnecessary inventory purchases.

Strategically speaking, accurate demand forecasting should work alongside your replenishment cycle. Getting your forecast as close to accurate as possible is only half the equation. Next is mapping out when and how to order your new stocks when preparing your reorder schedules every succeeding period to avoid the bloated costs of overstock.

If you have an online store and a brick-and-mortar store, there should be a unique reorder point for each SKU in each outlet. Automatic replenishments are worth looking into to save you the time it takes to compute manually. There are smart tools like Inventoro that can analyze your SKUs’ optimum reorder points, prepare purchase orders, and automate order placements, so you won’t have to repeat the process each period.

Another way to avoid overstocking is to work with third-party logistic providers. They aim to expedite your logistic operations and reduce processing costs while freeing your warehouse space from extra inventory. Consider them your ally in packaging, warehousing, fulfillment, and customer distribution.

“The exceptional service from 3PL providers is tailored according to the unique needs of each business, so online retailers can scale up with complete peace of mind that their order fulfillment is in the safe hands of ecommerce experts,” claimed Alex Borg, Product Development Manager at Zendbox, a fulfillment solution provider.

3PL providers analyze individual items and compare them to the inventory on hand (basically, like a third-party inventory audit). They can remove bottlenecks in the selling and distribution phase to eliminate return stocks from unfulfilled sales.

The dangers of overstocking don’t only happen during stock inflow (i.e., purchasing and sorting phase). Your stock control can also be more reliable and secure if you streamline your allocation and delivery processes.

By performing an inventory audit, you make sure that your current records align with what you actually own. Your sales forecasts and replenishment strategies are futile if your documents are inaccurate and misleading. To avoid overstocking due to erroneous reports, inventory audits must be conducted regularly and not only on ad hoc occasions.

Inventory counts keep track of the physical items in stock on your sales floor and in your warehouse. Your team can do it faster using devices together with your POS system. After tallying the count, you can compare the result to the records and make necessary adjustments in case of a discrepancy.

Overstock reduction relies on accurate reports and records, making auditing one of the most important tasks. But if you can’t risk interrupting your store hours to conduct one, consider cycle counting or partial counting. If you have an apparel shop, you can apply the same practice gradually to a small group of products (e.g., shirts, coats, pants) each week. It’s the easiest way to keep your data accurate and stock levels well-controlled.

Product segmentation is a business intelligence tool that gives you a bird’s eye view of your inventory. Understanding which products end up in dead stock helps reduce surplus inventory. With this knowledge, you can enhance your product portfolio and stop purchasing slow-moving items that would only sit on your shelves for months.

ABC analysis is a famous inventory management technique for analyzing these product categories. It ranks your most in-demand items from A to C, A being the most profitable and C being the least. It ranks your most in-demand items from A to C; A being the most profitable, C being the least. Inventoro follows the same principle by analyzing your Winners, Chasers, and Losers.

Sorting your inventory this way can also help avoid regional overstocks. If, for example, you noticed your parkas selling out like hotcakes. So you boosted your orders by adding 300 SKUs per store. But if you zoomed in and sorted your winners per warehouse or shop location, they only fly off the shelves in the Northernmost locations, not everywhere else. If you could glean this useful insight, you would have only purchased the right number of parkas.

Supply chain disruptions and fickle market trends are inevitable, but you need to keep tabs on them to strengthen your forecasting skills. “Overstocking has become a common practice, especially after the pandemic. However, with uneven market patterns, overstocking is doing businesses more harm than good,” explained Rakhi Oswal of Edrio, a premium athleisurewear.

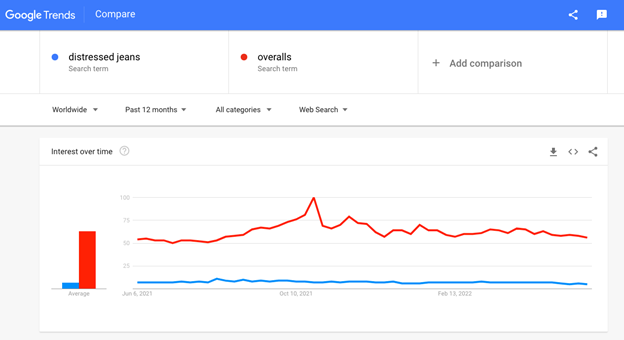

You can use free technology to dig more predictive analytics, such as Google Trends. It’s an easy way to assess product interest in a definite period.

Let’s say your online apparel shop needs replenishment, but you’re unsure whether to prioritize distressed jeans or overalls. Using Google Trends, you’ll know the answer in a few clicks. As shown below, overalls have higher interests—and thus, more profitable—than distressed jeans. You can also compare more than two products or specify your country and subregion for more accurate results.

Analyzing previous stockouts and extreme sales algorithms can also be useful. During uncertain times, these insights can help you adjust forecasts on intermittent items to improve sales forecasts–especially when predicting the demand for seasonal and promotional items.

But analyzing economic situations is a bit more complicated. “When everyone was at home [during the COVID-19 pandemic] and wanted to feel more luxurious in their lockdown, higher priced goods sold more. After the peak, with inflation and news of economic recession dominating, consumers begin to pull back and look for bargains,” explained Leanna Serras, Chief Customer Officer of FragranceX.com.

By gearing your company with advanced forecasting abilities that tools like Inventoro provides, you can simulate unpredictable scenarios, such as pandemics and recessions, and find out how much stock to keep on hand.

Advanced analytics is always better than guesswork, so use them whenever possible.

Imagine if you have paper-based records for your brick-and-mortar and Excel documents for ecommerce. It would take forever to encode your sales and purchases and upgrade the record balances. In short, you can’t use these data as a basis for accurate demand predictions or physical counts. So ask yourself: Are your purchasing decisions objective enough when it doesn’t reflect real-time information?

Using single inventory management software for all platforms will allow for better monitoring, recording, and decision-making to prevent overages. It could help you avoid juggling multiple sources and manually consolidating data.

Opt for inventory management systems that can hold vast information, including each SKU’s reorder points, location, and ideal level. It even tracks and records the movements of each product from purchasing up to the selling point. These records and reports are in a single data source to let everyone access the updated data 24/7.

Learn more about choosing an inventory management system that works with your business infrastructure here.

Sustaining well-optimized inventory levels takes a village. The purchasing, sales, and logistics departments must understand their roles and work together to avoid overstocking. You can only maximize the benefits of integrated inventory software if everyone understands how it works.

Your staff has first-hand knowledge of the actual business on the sales floors and the warehouse. They know what products are popular and which are not. Equip them with the skills and tools to put this familiarity to good use by encouraging them to suggest ways to improve current inventory processes and providing feedback on which products are performing well.

Educate your team on overstock inventory and how they can contribute to averting it. You can also offer opportunities to maintain optimal stock levels, such as training on inventory systems and internal processes.

Overstock inventory emanates from internal and external factors. Some are avoidable, others not at all. Nonetheless, there are best practices to mitigate their impacts, such as accurate forecasting, optimized replenishment, improved internal processes, and advanced third-party tools.

Inventoro is an inventory management tool that helps you eliminate excess stock. The key is automating purchase orders, optimizing your reorder points, and ensuring that you stock up on bestsellers.

Don’t let the dangers of overstocking crush your bottom line. Request a demo today.

Become a retail mastermind you always wanted to be.