Sales forecasting

and inventory optimization

Become a retail mastermind you always wanted to be.

Become a retail mastermind you always wanted to be.

By: Jul Domingo

When ASOS opened a new warehouse in the US, inventory ran out. Orders from customers piled up.

Despite having multiple warehouses and a large apparel inventory, the ecommerce giant failed to fulfill its shoppers’ demands. Coupled with technical gaffes, the former darling of the UK stock market saw its shares plummet by 68%.

If inventory-related issues can have such a significant impact on ASOS, an online fashion powerhouse, it can do the same for your small to medium-sized ecommerce businesses.

But the good news is that foolproofing your inventory doesn’t require a huge investment. In this article, we’ll share with you 5 simple ecommerce inventory hacks. Each tip is tailored to the needs of your ecommerce-focused SMB:

Historical data plays a huge part in your inventory. But are you sure you’ve captured it correctly?

Most ecommerce businesses fall into the trap of increasing the stock level in their system, thinking this is a smart way to avoid out-of-stock issues and keep their customers happy.

On some occasions, the wake-up call comes immediately–when you’re grappling to replenish your stocks and have to apologize to your customers for delivery delays.

If you’re lucky enough to escape this mishap after carrying out the act, one thing’s for sure:. You can’t escape how it impacts your ability to forecast inventory accurately. You don’t have an accurate picture of what you need.

Without giving your data a good scrub, you’re putting yourself in a catch-22 situation. Inaccurate data, inaccurate forecasts. So roll your sleeves and get to correcting your inventory numbers. There’s no shortcut for this one, but hard work.

Fortunately, you can do regular inventory counts to make sure your data remains clean moving forward. In general, we recommend barcode technology software for ecommerce brands with a high stock level. Manual physical counts are only good enough for smaller organizations.

There are many ways to segment your products. But from an inventory standpoint, you need to classify them according to their performance and your strategic objectives.

ABC analysis is a common approach here. This technique determines your inventory value by analyzing how important inventory items are to your business operations.

If you prioritize profits, your identified winning products are those that bring the highest margins. But it’s not necessarily going to be the same products that fly off your online storefront’s shelves. Sales quantity will most likely be the criterion for the latter.

Once you’ve identified your top-performing products, high-potential products, and products that treat your warehouse as their forever home, you can focus on doing the following.

Inventoro tip for our users: We give you the option to focus on different strategies–Profit, Revenue, Sales Frequency, and Sales Quantity.

The effects of recent years have taught entrepreneurs like you to become more flexible when forecasting sales. Complex formulas and basic software tools are sufficient to perform the tasks, but they don’t take unforeseen circumstances into account.

Moreover, forecasting shouldn’t be a complex calculation-intensive activity driven by top statisticians. This approach requires hands-on work, which isn’t for everyone nor is it advisable.

Smart, otherwise known as automated, forecasting software is key to more accurate predictions. It saves time and eliminates human error, which accounts for 70% of data loss or business failure. Automation doesn’t imply that you don’t have control over forecasts. Because you know your business better than anyone else, it’s only natural for you to contribute.

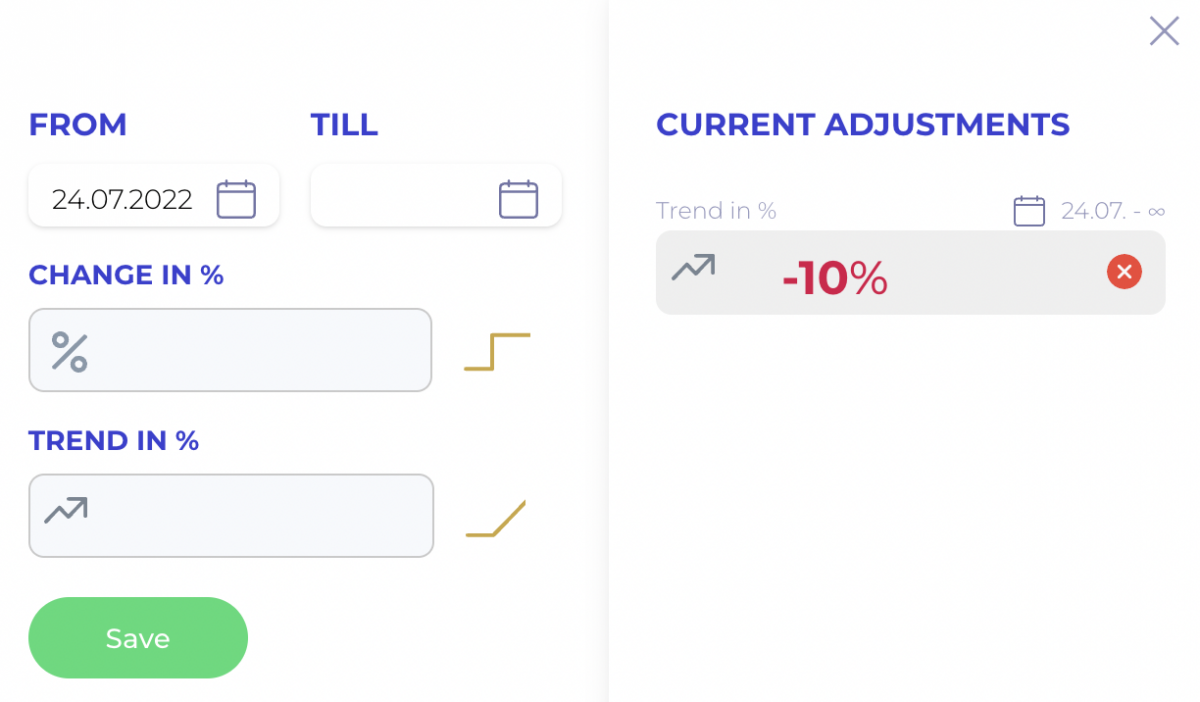

At Inventoro, we add simple buttons to help you influence the system with more business-related information. Our forecasting adjustment tool allows you to modify the trend during periods when your company feels or anticipates additional or different customer demands.

For instance, after putting out shoppable links or social media ads, you might expect an increase in your sales. You can factor your prediction in by tweaking either the “Change in %” or “Trend in %.” Learn what the differences are here.

Making your sales forecasts more accurate can improve your business dramatically. They affect different areas of your business–from inventory to product dev to finance. If you’ve forecasted to sell a particular product well several months out, you can use the estimate to improve your cash flow by negotiating a better deal with your supplier.

Inventoro tip for our users: We make this info easily accessible with our “merge order” toggle.

Establishing reorder points helps retailers answer a fundamental, recurrent question: When should I order new stock?

Toeing the line is key here When you order ahead of time, you’ll have to worry about crowding your warehouse. When you order a little later than you should, you may lose out on potential sales. So you want to have a healthy amount of safety stock. Automating the replenishment process removes the guesswork in the process.

It’s common practice for ecommerce entrepreneurs (or any retail business owner, for that matter) to predict sales for a certain period of time. It’s safe to assume you already do this for your business. But sales forecasting accurately is only one part of the process.

There are many other parameters to consider when replenishing your stocks. At Inventoro, we also place a great deal of emphasis on your shelf availability to keep you from overbuying. It’s a conservative approach that allows businesses to satisfy customers without taking excessive risks. We then create a list of suggestions for product replenishment ready for your evaluation.

Saving time and effort is another reason to automate stock replenishment. Studies show that 59% of workers believe automated processes, in general, can save them up to 6 hours per week. In our observation, automating the process of calculating balances and creating order lists can save you up to 20 hours of admin work each week. There’s also the benefit of freeing your brain from lead time-related worries.

Playing around with formulas, Excel sheets, and calculators may seem an easy way to determine reorder points at first glance. But it can turn into a pain point just as quickly. Replenishing your stocks carries a lot of weight for your business success–these outdated processes will only bury you deep in the weeds. You need a smart system that can factor in your forecasts and figure out how many products you’ll need by when.

Despite the convenience of automation, it’s understandable if you’re interested in learning more about the trends that could impact your decision. At the end of the day, it’s your business. Taking what your tools give you at face value limits your ability to effectively use the available data to reduce inventory costs and increase profit.

Below are some examples of inventory reports you can glean insights from:

By reviewing the data presented in these inventory reports, you can make more intelligent business decisions to maintain customer satisfaction and increase profitability. The information also helps you understand how much capital you have tied up in your inventory items.

Inventoro tip for our users: These reports are already available for you to generate in a few clicks. But you can contact us if you need a special report, and we’ll put one together for you.

IT problems also plagued ASOS, contributing greatly to their warehouse difficulties. Ultimately, this is the result of opening two giant warehouses without being prepared for them.

The tips outlined above will help you grow mindfully and become more aware of what your business needs.

If the time comes for you to expand, even on a smaller scale, keeping your data clean, bringing your overall business strategy into focus when making inventory decisions, automating some inventory management tasks, and studying your data will grease the expansion wheels and let success roll your way.

Become a retail mastermind you always wanted to be.