Sales forecasting

and inventory optimization

Become a retail mastermind you always wanted to be.

Become a retail mastermind you always wanted to be.

Inventory management is a field of supply chain management, and as such, it belongs to the most complicated tasks of humanity. At Inventoro, we wake up every morning just to make this field as understandable and straightforward as possible for all. Spend some time with this text, and you’ll get a basic understanding of what inventory management is and how to mastermind this field.

There are two ways of how one can consider inventory management. From one perspective (the most common one), it is the art of sorting and labeling within your physical warehouse. How you divide shelves, how you barcode your products, what process you install above these tasks. But that’s just the basics.

The second view of inventory management (and the one we are going to discuss) is much more about the big picture and the ultimate goal of keeping a lean inventory. A large inventory is expensive in so many ways. It holds operational cash. It holds warehouse space, and it requires more staff to handle. And at the same time. A large inventory doesn’t bring benefits. It’s a pure business pain.

But keeping a lean inventory is extremely complicated. It requires maths and extended computer power to get it right. The possibilities of everything are so vast that finding ways to reduce inventory is far beyond the limits of a human brain. Think of it as weather forecasts. There is no way to create accurate weather forecasts by looking at clouds and trusting human intuition.

Clever inventory management leads to the ultimate goal – small inventory. Obviously, this goal cannot and must not stand in the way of your business and customer satisfaction. The trick is to reduce inventory while keeping your product items available for sale.

This is done by searching for the perfect balance between too much inventory and not enough inventory. Finding the ideal middle spot is the holy grail of retail, and it should be every shopowner’s goal.

Inventory management is the last and most significant discipline in retail, reducing your costs by a substantial portion. You cannot really significantly reduce your staff pay; you can’t negotiate substantially different prices with suppliers overnight. But you can reduce your inventory by tens of percentage points. It can push your business form a “positive zero” to a profitable, sustainable enterprise. No other retail discipline has this opportunity.

Become a retail mastermind you always wanted to be.

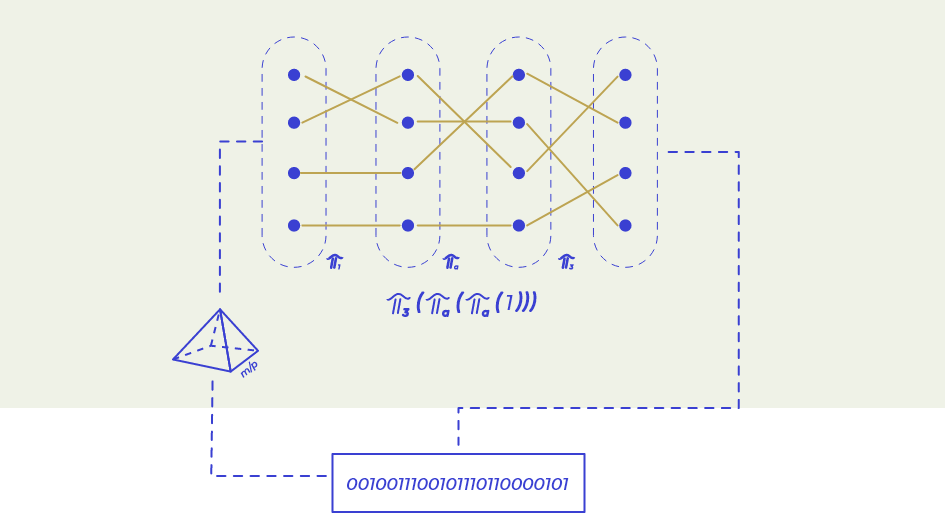

This requires a lot of computational power, but it is possible and proven in time. Understanding numbers is much easier for a computer than understanding human language, for example.

It is no wonder that supply chain management has been among the first fields where AI and deep learning have been industrially applied. After all, algorithms need data, and inventory management creates billions of data every day. Making it the perfect field for automation.

Even Inventoro was born from an industrial solution. It’s a typical story of IT solutions, which were first created and adopted for the biggest companies on the planet. As technology advanced and got cheaper, inventory management became a possibility for all. Cheep, yet still reliable.

So if you don’t know what inventory management is all about. Now you know. So let’s take a closer look at how it’s actually done and what can you do every day to reduce inventory while keeping your stock available for sale at the same time.

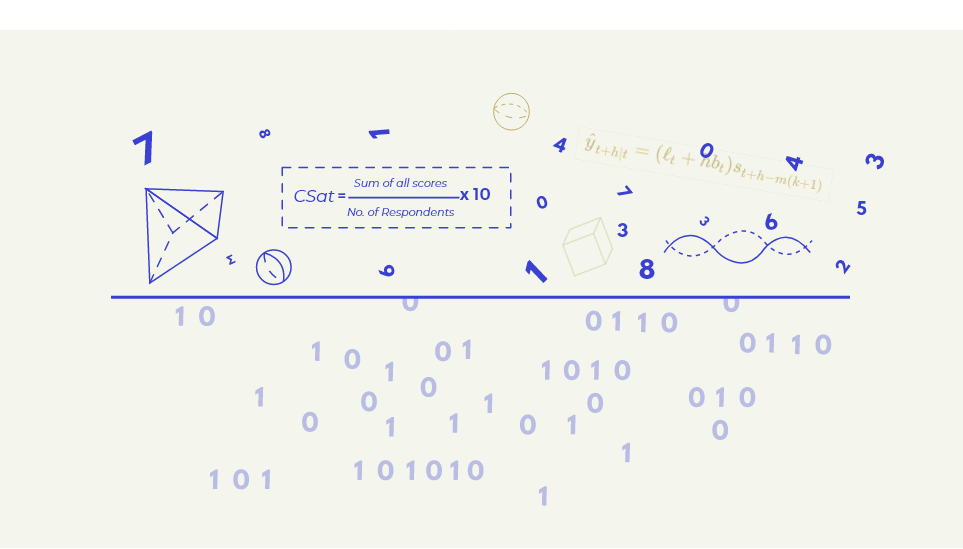

First and foremost, you need to start forecasting sales. If you can’t accurately predict how much you will sell in the future, then inventory management will remain a mystery for you. It’s an essential building block for any inventory optimization. Only those who forecast well have a chance to make a difference in inventory size over time.

Sales forecasting is a mathematical task. The methods and equations of forecasting have been around since the mid 20th century and continue to improve until today. But it is definitely not the case that a new method replaces an old one.

We see that artificial intelligence and deep learning are helping the traditional models get better over time. But only together can they really make a difference. So typical companies, which forecast well, use many algorithms for forecasting, and then they evaluate them, score, and compare their results.

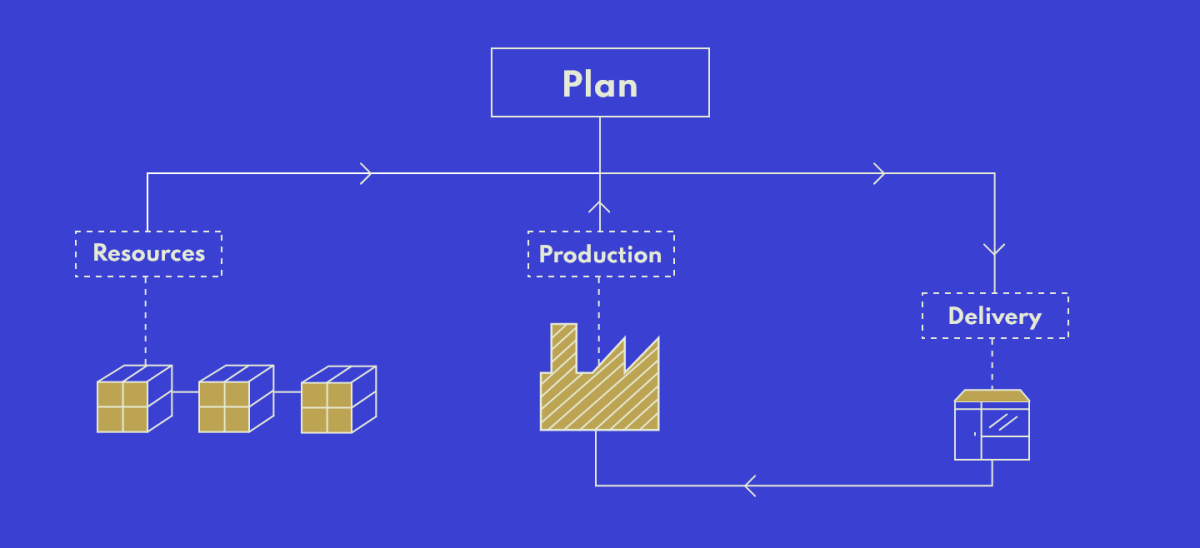

The next step to inventory management is controlling the activity, which has the most significant effect on your inventory structure – orders. Why orders? Because at the end of the day, your inventory is only as big as how much goods you order form your suppliers to fill your stock.

The more clever you are in making correct orders, the smaller your inventory will be. The trick and the holy grail of supply chain management are to order as little as possible, but still enough to satisfy customer demand.

Ordering too much means your warehouse will grow, and you will hold a lot of operational cash in goods lying in your inventory untouched for weeks, months, or even years. Ordering too little leads to stockouts. That’s the moment when customers come to your shop or e-shop ready buy, only to find out you ran out. A large inventory is bad. Stockouts are even worse. Smart inventory management means you avoid both.

And that’s the moment when we come back to forecasting. The logic is simple: to make smart orders, you have to be able to create highly accurate sales forecasts for each item alone. Because if you know how much you will sell in the future, you are in a perfect position to create smart orders based on data rather than intuition.

So the basic element of inventory management is clear now. Do a good job in demand planning and make smart everyday decisions about orders, and you are all set. Eventually, your inventory will become smaller, and your goods more available.

And now, to make things a bit more complicated, we are going to discuss service level. Because keeping all goods available at all times might not be the smartest decision after all. If you’ve read this far, chances are you wish to become a committed smart inventory planner yourself. And a smart inventory planner will divide her products into several categories. To make it easier, let’s start with three basic ones.

The cash cows or the goods that sell very well and enjoy a continuous demand form customers on a daily basis. These goods represent a small fraction of your inventory, but create the most of your sales.

The second category is the bulk of your inventory. These goods don’t sell so often but are still profitable. They create the size of your offer and are crucial for customer satisfaction. The last category is your inventory trash. These are the items nobody wants to buy. They just sit in your inventory and hold your warehouse space and cash. We in Inventoro call these Winners, Chasers, and Losers. In the world of supply chain managers, this is called an ABC analysis.

Avoiding stockouts is essential. But it is more important for your best products. Your inventory trash is something of which to get rid. So it can have stock out all it wants. And how available each product is defined by service level. It’s measured in percentage, and it basically says: “Out of 100 customers, how many will find their desired product available no matter what happens.”

So you, as an inventory manager, want to start making clever decisions about the service level of your products. Inventoro helps you to make product segmentation automatically and recalculate it every day. So you don’t have to do it by hand – which is close to impossible by the way.

The way we set up service level in inventoro looks like this:

| Winners | Chasers | Losers | |

| Service level | 99% | 95% | – |

Let’s look into the numbers a little bit.

Become a retail mastermind you always wanted to be.

Chasers are set at 95% because there is a lot of those. And an occasional stock out here and there doesn’t harm your reputation to a great extend. Remember that chasers are a large group. On an inventory of 20 000 SKUs, they could easily represent 16 000 SKUs.

95% for Chasers is more than enough. Remember that you also create a strain for cash and profit every time you increase the service level. However, if you keep your service level too low, you are likely to face a lot of stockouts, which will damage your customer satisfaction. If users can’t buy what they need at your shop or e-shop, they are not very likely to come back. 95% for Chasers is just about right and just the perfect compromise between the customer and profits.

So let’s just recap before we go to the last part. You start with forecasting. The demand planning tells you how much you will sell most probably. Then you have your service level, which means you how much extra items you need to order to supply demand. Once you know how much that is, you are ready to start making smart orders to your suppliers. Follow this process every day over time and watch your inventory reduce in size, and the availability of your goods increases at the same time. Get this right, and you can call yourself an inventory manager. Or just simply leave the job to Inventoro as we do all these steps automatically and every day.

We explained the basic elements of inventory management: demand planning, service level, and smart replenishment. We say basic because inventory management or supply chain management is hard. It’s so complicated that the world’s best supercomputers try to get it right and still are near perfect. However, for basics, you are covered, especially if you use our app, which automates the whole process and does all the calculations for you every day.

The fun part starts when you have more than one warehouse. Now your warehouse doesn’t necessarily have to be a physical house. It can be just inventory you keep in stock in the back of your shop.

So let’s consider you have an e-shop, three retail shops, and you also function as a wholesale business. All five stages sell the same goods under the same enterprise, and yet as a good inventory manager, you want to treat your segments as individual entities working for one bigger company.

So the process of demand planning, service level, and smart orders has to be done individually for each of your customer touchpoints. And it is not that hard to imagine why. Let’s say that you sell sporting equipment, and you have one shop in Colorado and one in San Francisco. Chances are your mountain shop will find skiing equipment in Winners, and your San Francisco shop will have the same for surfing equipment. Change the location, and the numbers are the exact opposite.

The way to solve this is to create a tag for each item containing where it is based. In reality, if you sell items on five locations, you have 100 000 items as a matter of fact. You want to calculate demand for each item alone and each location alone as well because your order lists will look different based on where they are.

In all cases, Inventoro has you covered. Every SKU in our app is treated and calculated based on its location, and once you use our system, you will find that our order recommendations are site-specific precisely for this reason.

Become a retail mastermind you always wanted to be.