Sales forecasting

and inventory optimization

Become a retail mastermind you always wanted to be.

Become a retail mastermind you always wanted to be.

Key takeaways:

At the beginning it is good to understand the role of inventory in a company. In general, Inventory management is how you can make sure your customers can spend as much money as possible at your company. This means keeping products available for sale, offering customers the products they want to buy, and not keeping unnecessary overstock, all at the same time.

Inventory management is the ability to enable your customers to spend maximum of their money in your company

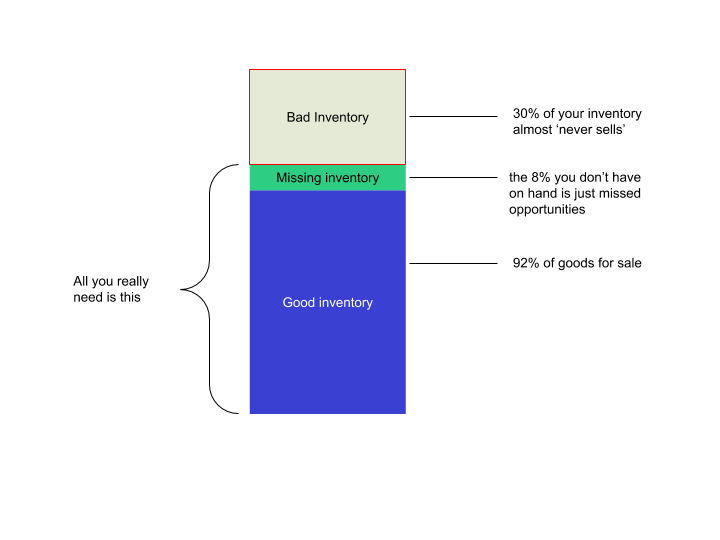

Every stockout, every elimination of inventory due to expiration, every error you make in your inventory control – these are examples of situations when your future customer is robbed of the chance to spend more money in your brick and mortar store or e-shop. You know you need inventory to satisfy customer demand. SMEs (small and medium-sized enterprises) are able to meet that customer demand 92% of the time on average. Different people call this different things: the ability to deliver, the ability to satisfy customers, service level, fill rate, or on-shelf availability. But it doesn’t matter what you call it. The fact is that when you don’t have inventory on hand for sale, you disappoint your customers. They walk away from their shopping experience unsatisfied. On the other hand, the average SME keeps 25-30% excess inventory. That’s right. The same company that can reach just a 92% service level has excess inventory just lying around the warehouse. Is that not a paradox?

Keeping the right amount of inventory and the right products in that inventory is the key to success (especially in these days of volatile sales due to Covid-19).

In this article we would like to help you with inventory reduction, also known as optimization. We will show you what specialized software like ours can do to help you, but we also give you a few approaches that don’t need any special solution, just common sense and your ability to decide.

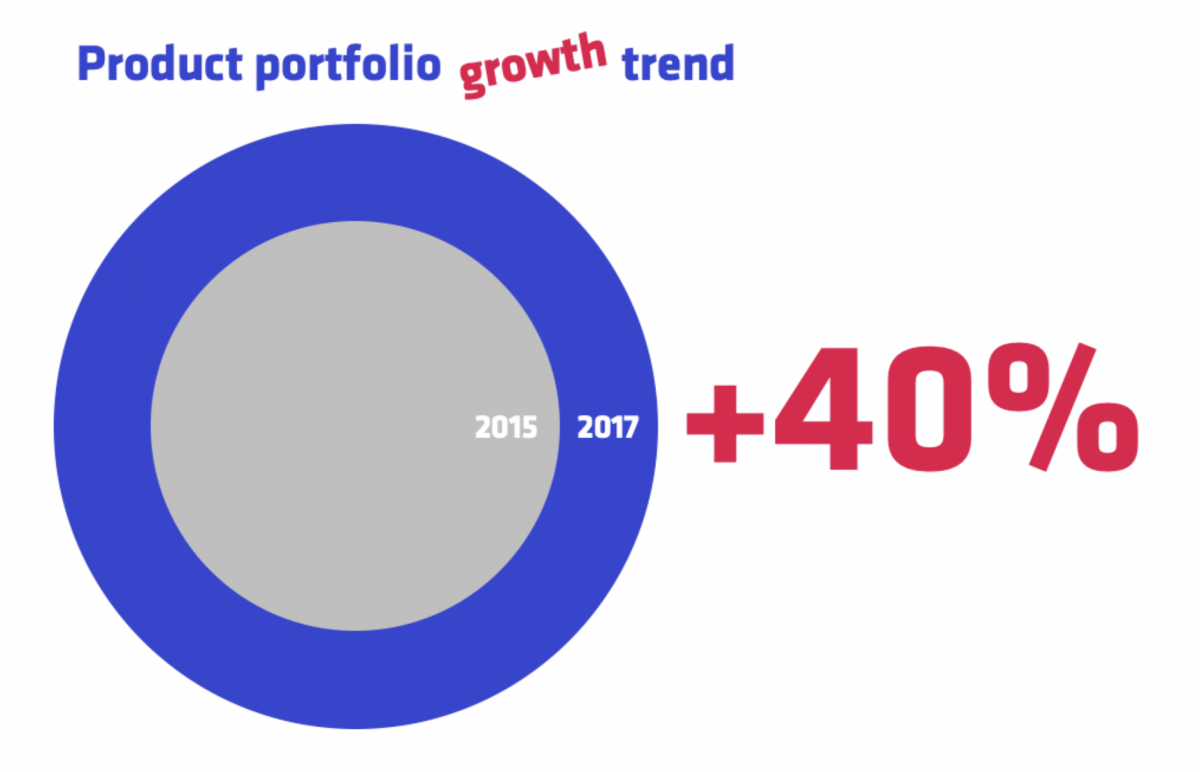

The continuous growth of inventory seen in the last several years is illustrated by the fact that an average company has 40% more products in its portfolio than two years ago. 40%! That’s an enormous growth of complexity in ordering. In the e-commerce world this number is even higher, because in the digital world it is quite easy to add new products and keep them sitting around in your e-shop for months, even years.

It’s easy these days to prepare the data necessary to use specialized software for sales forecasting, inventory management, and optimization. All you do is prepare historical data of your sales, inventory on hand, and lead times of your suppliers, and you’re good to go. With programs like Inventoro, it’s a simple step to connect your data computer through Shopify, for example.

A specialized solution like ours can calculate accurate sales forecasts for every item in your portfolio, even for every item at a certain sales location (usually store or warehouse). With information like current on-hand inventory, real supplier lead times, and other data, these solutions can calculate optimum inventory levels and optimum purchase orders. After execution of these optimum proposals, you eventually reach an optimum inventory level. Hundreds of customers around the world using specialized software solutions like our solution Inventoro have seen an average 25-30% decrease in inventory but also a 10% increase in service level (customer satisfaction), which means an increase in both revenue and margin.

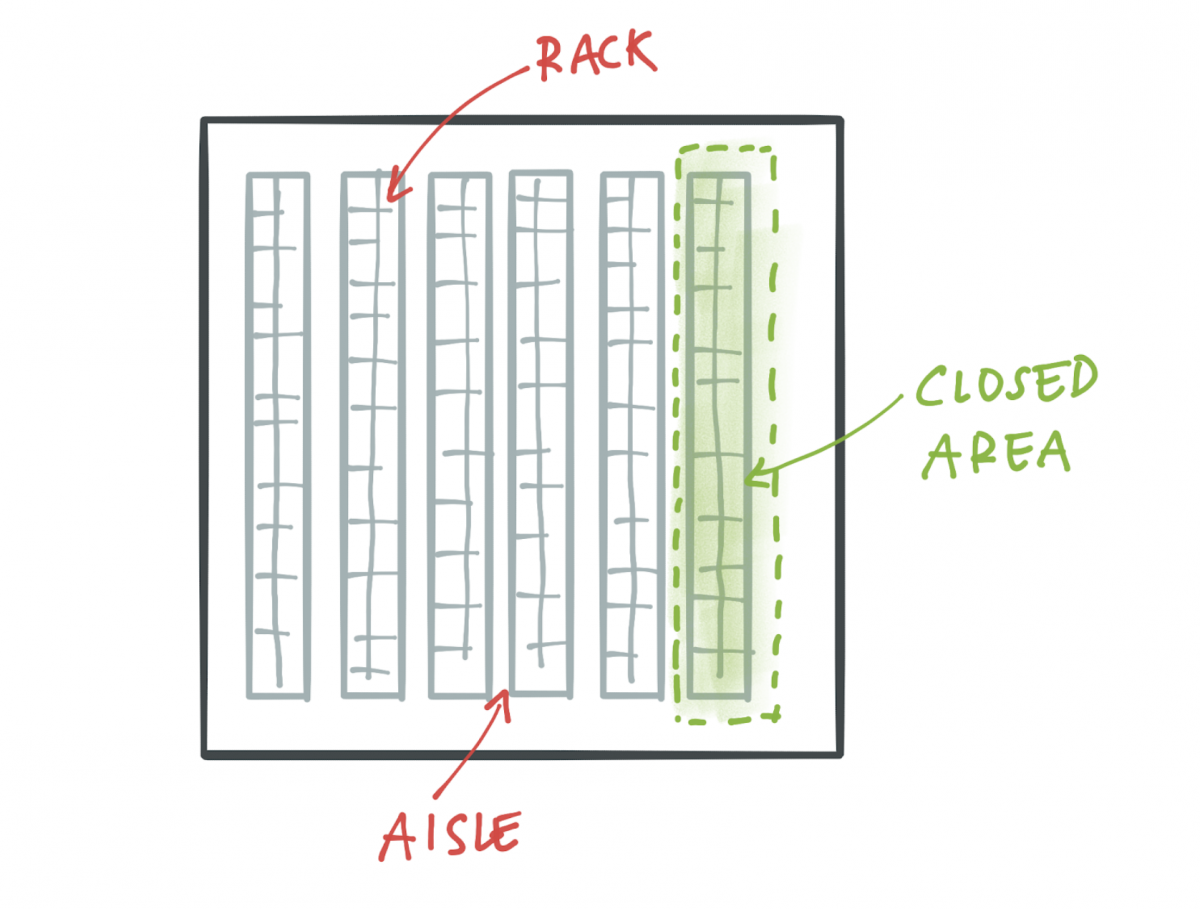

There is a quick way to reduce your inventory without any special software solution, but it’s more like a trick or quick fix than a real solution. Imagine your warehouse, full of racks, aisles, and workers. If you need to decrease your inventory (working capital) very quickly, just close one whole line of racks. You can use wire mesh or some other barrier like a bar or some other divider. Be creative. What will happen? People are flexible, they can learn how to purchase new inventory in a smaller warehouse very quickly. They will find ways naturally and easily. But remember, this solution is good only for the short term.

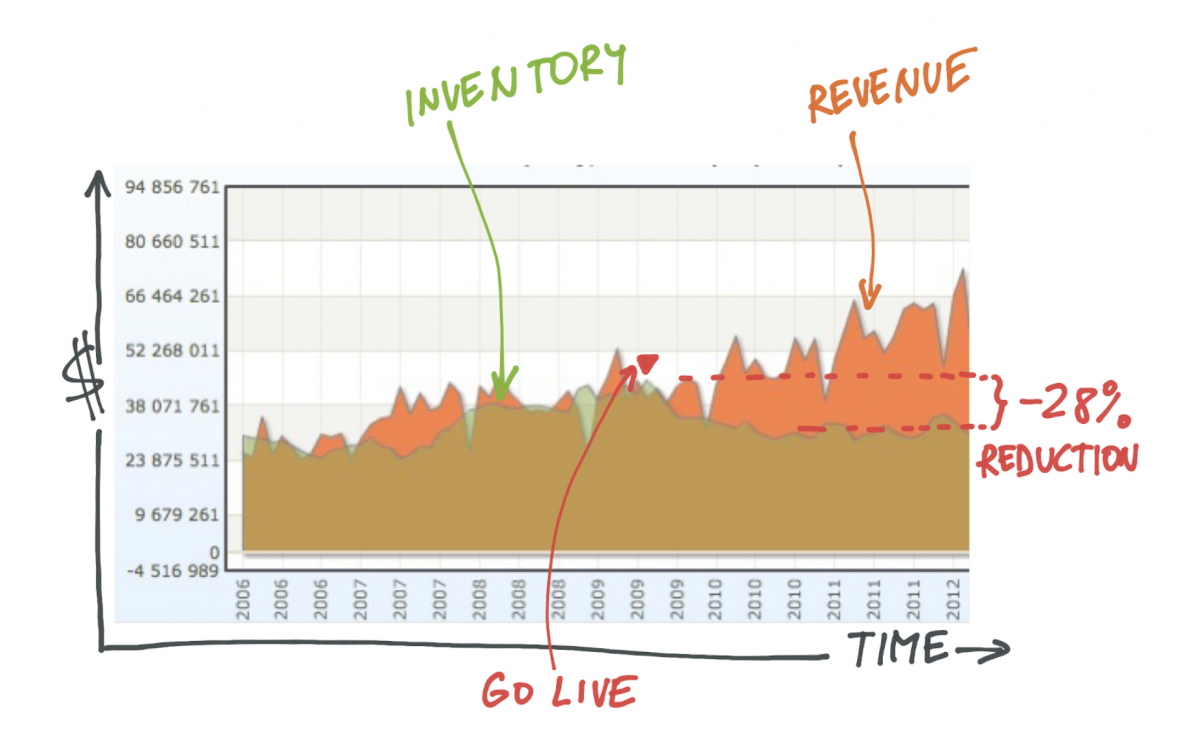

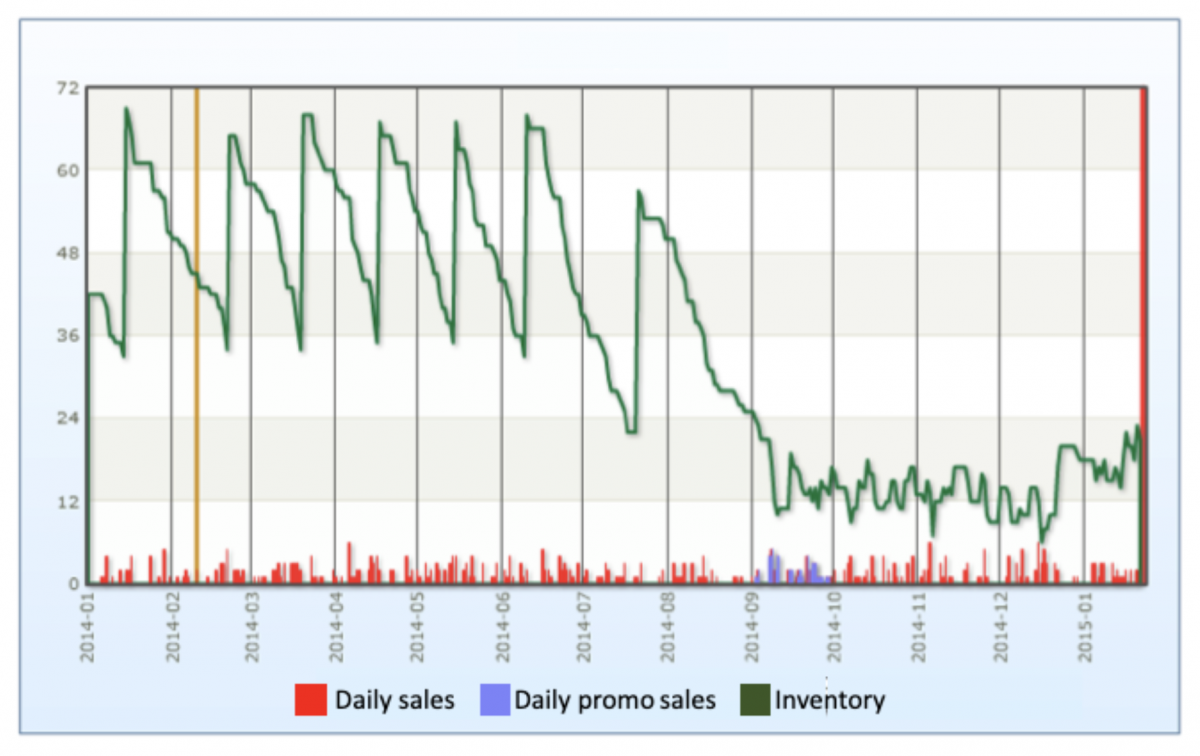

The first example of real inventory reduction we’d like to share here is from a company we’ll call FMCG. Small FMCG has customers from retail, both big and medium-sized players. After implementation of an advanced solution for inventory management and optimization, the same technology as Inventoro uses, the company was able to reduce inventory by 28% in just a few months. This inventory optimization went hand in hand with a rapid increase in revenue. When inventory is optimized, you can see that even when revenue grows, the value of your working capital is basically the same. By the way, this is one of the most important benefits of using technologies like Inventoro: consistency of results. You are able to optimize inventory every day.

The example of this company is striking: Since 2010, their revenue has more than tripled. And they’re still in the same warehouse.

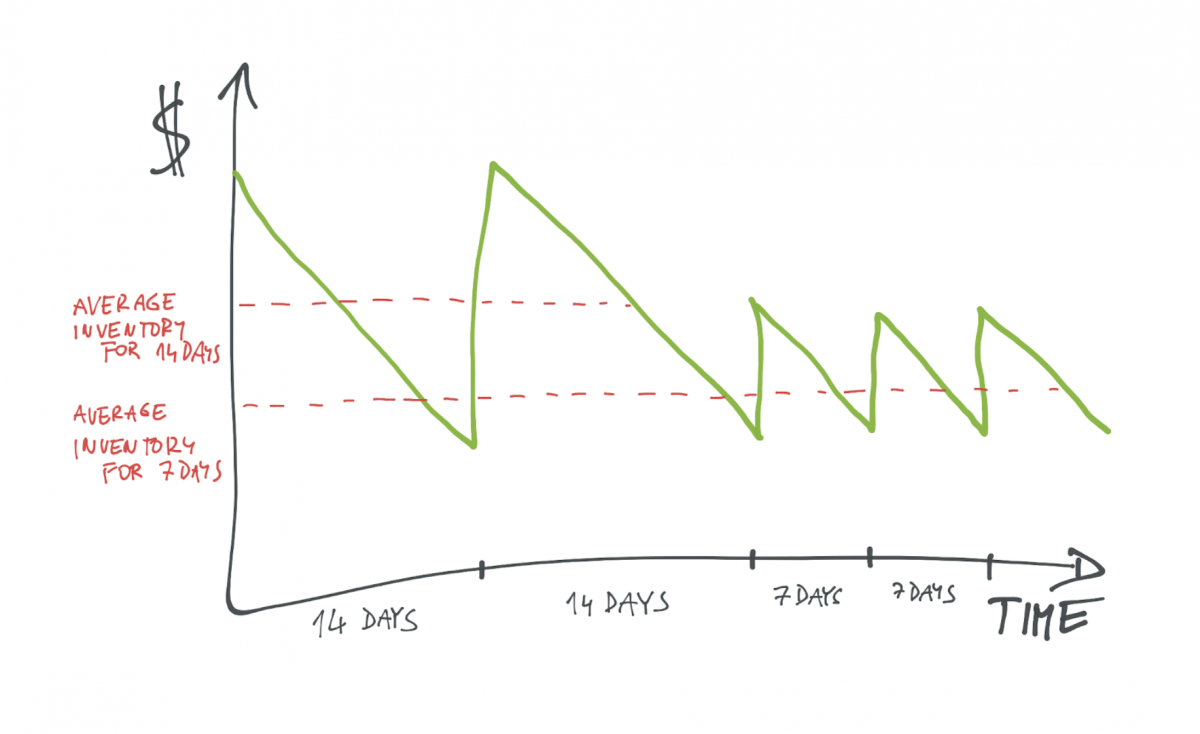

One of the most useful methods that doesn’t require any special software is shortening order period. If you are used to purchasing every two weeks, try reducing that period to one week. It’s not very complicated. The downside is that you have to have the time and manpower necessary to create more orders and receive smaller deliveries more often. That can be a strain on any business, big or small.

The picture below illustrates this method in the real world. You might ask why we chose this extreme example. It’s simple, because it is this kind of example that shows the possible trap of this technique for inventory reduction. Can you see the big disadvantage of this technique? There is a risk that you will start to purchase a smaller amount of product from your supplier, and very often this means that you have to pay more because you order less. So you have to decide what’s more important for you. Do you prefer lower working capital (inventory) with the possibility of higher purchase prices, or higher working capital with optimal purchase prices?

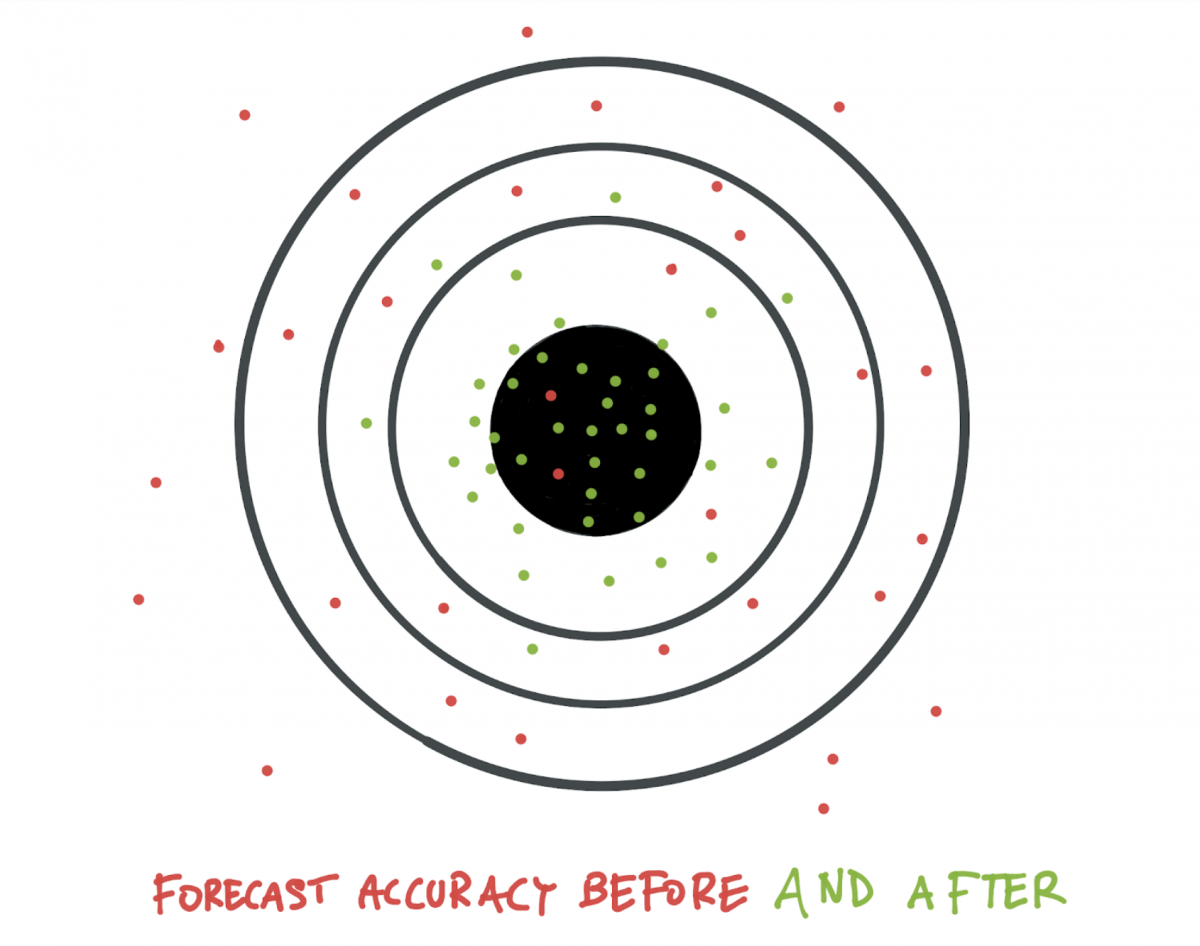

When you start using software for sales forecasting and inventory management, you should see immediate improvement in forecast accuracy. Forecast accuracy basically means that your plan more accurately reflects your real sales. Then, when you get better forecast accuracy from the system, you should also get lower safety stock, the part of inventory that protects you against volatility in sales and volatility in deliveries from your suppliers.

This is directly connected to the finding we mentioned previously. An average company has 40% more products in its portfolio than it did two years ago. This leads to higher complexity and logically to more inventory in the warehouse. Sometimes companies see something like in the picture below. This is an example from product segmentation in the Inventoro app. You can see that the system shows you don’t need 4,557 SKUs in your portfolio it categorizes as “Losers”. This represents almost 60% of your inventory, but it makes up only 3% of your revenue. And the worst thing is that there is no profitability.

Eliminating dead stock isn’t easy. But there are some ways to do it.

If you want to reach your inventory reduction goals, you need a good inventory reduction plan. Here’s an example of an inventory reduction plan:

We’ve given you all the information you need to do it on your own, but knowing what to do is not actually doing it. Don’t be fooled. Without experience, good math skills, and a fair amount of time, it’s not nearly as easy as we have made it sound (and if you don’t believe that, try it yourself without the help of a software solution like Inventoro). And now, if you’re ready to take a giant leap into the 21st century of automatized, software-driven solutions, please try our solution, Inventoro.

Become a retail mastermind you always wanted to be.