Sales forecasting

and inventory optimization

Become a retail mastermind you always wanted to be.

Become a retail mastermind you always wanted to be.

Key takeaways:

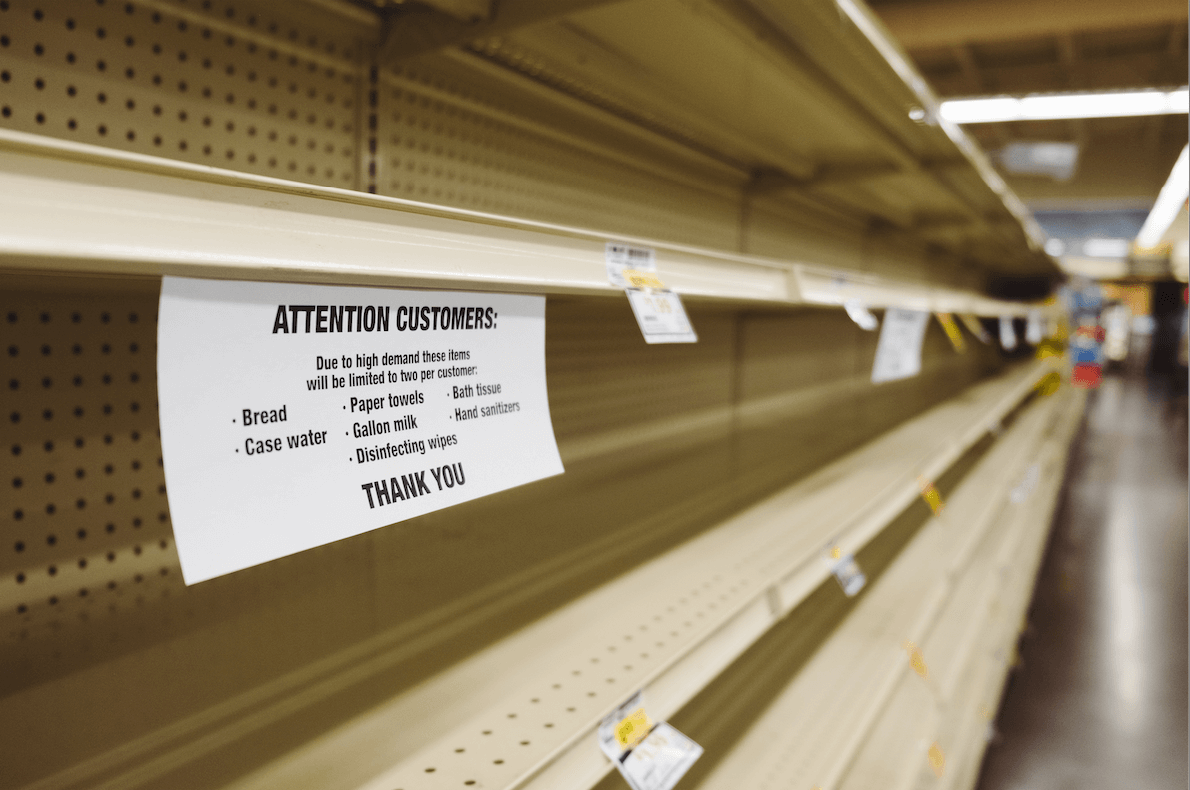

Everybody has been there. Everybody has stood in front of an empty shelf at least once in their lives, wondering why that shelf was empty. Both customers and retailers hate this situation. Unsatisfied customers feel cheated, and this can cause them to explore other options, find other retailers who can satisfy their demand for the products they want. On the other side of the equation, retailers are losing money, in the form of lost sales. So, how to avoid stockouts? How can you keep your customer demand satisfied, while holding less inventory? Is it possible?

A stockout or out of stock situation occurs when retailers don’t have the right inventory level and their customers can’t buy what they want. There are several reasons stockouts occur:

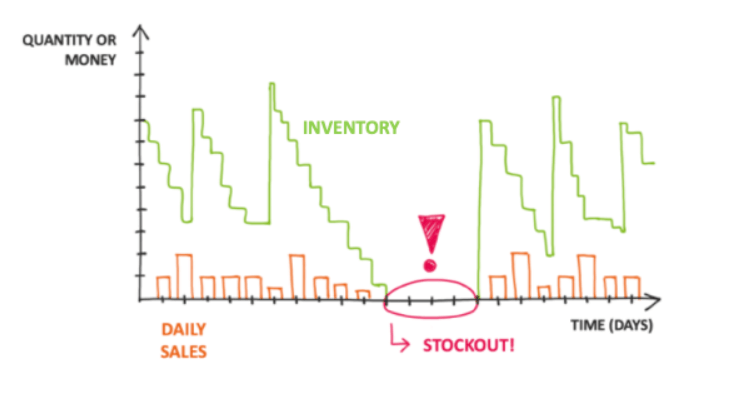

We can describe a stockout with the graphical illustration below. Time in days is measured on the x axis, with the green line representing inventory level and the orange bar graph daily sales. As you continue to sell to your customers, inventory level is lower and lower. When you hit zero or almost zero inventory, sales stop because nobody can buy that product.

This situation is called stockout or out of stock.

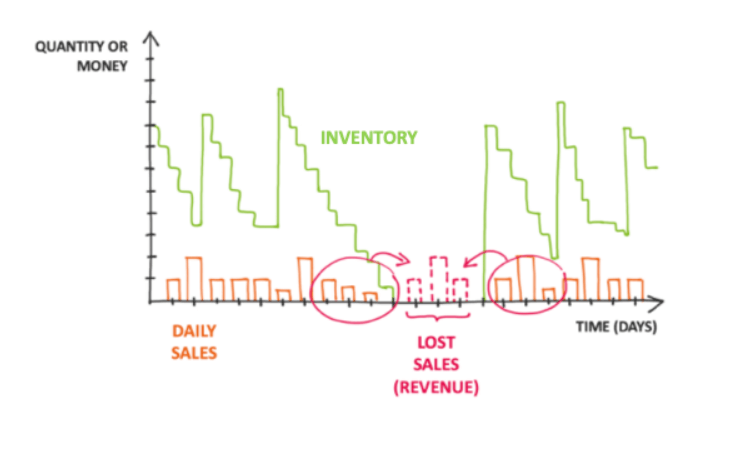

Stockouts occur in a limited time period, until the moment when you receive another purchase order from your supplier and inventory level is restored. From the moment when the stockout started until this time of refilling inventory, you lose the revenue connected to standard sales. These are lost sales. How does Inventoro compute lost sales? First, Inventoro automatically detects historical or current stockouts. Second, the zero sales period recorded during stockouts is adjusted automatically by Inventoro, replaced by an expected sales forecast, which means that Inventoro calculates what would have been sold if there had been enough inventory on hand. Then, after stockout, when the inventory has been refilled and you start selling the product again in the normal way, Inventoro compares real sales before and after stockout to take into account lost sales during the stockout. The principle we use is shown in the picture below.

Remember that lost sales during a stockout isn’t the only cost you have. An unsatisfied customer is an unhappy customer. There is a simple rule that “A happy customer tells three people; an unhappy customer tells 10 people”. So you have to act quickly. Real lost sales during a stockout is often only a small part of the real impact on your business.

It is standard that 92% of goods are available for sale in a typical small or medium-sized retail business. We hate stockouts at Inventoro, and we do all we can to help you avoid them. In the 21st century, when you can use advanced technology for sales forecasting and replenishment which can be quickly integrated with your ERP or ecommerce system, it is a shame, indeed an unforced error, to lose sales because of stockouts.

Give us a try, so we can show you the real benefits Inventoro can bring you and your business. Eliminate lost sales due to stockouts, reach up to 99% customer satisfaction, and do all that at the same time you reduce inventory, on average by 25%.

Sources:

Photo by Wesley Tingey on Unsplash

Become a retail mastermind you always wanted to be.